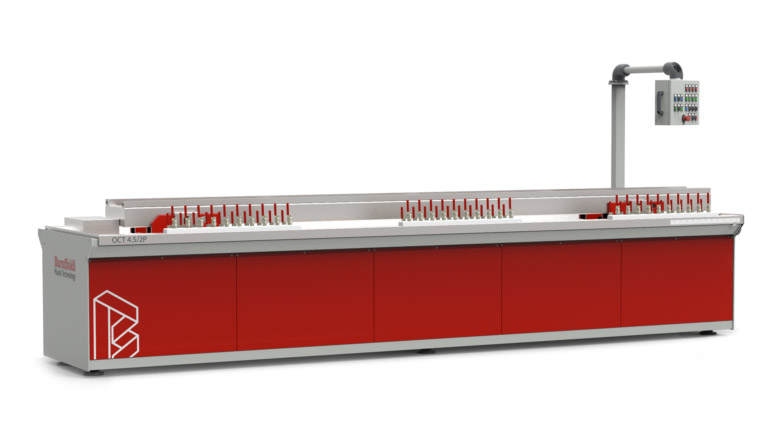

iCut

“Every great invention is born from a simple idea.

Then people define it brilliant”

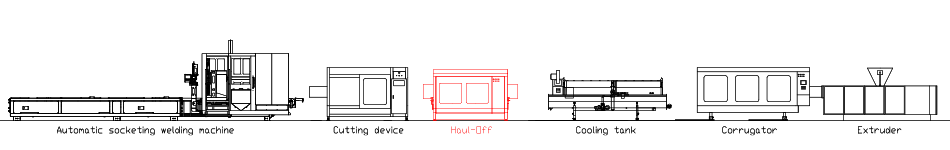

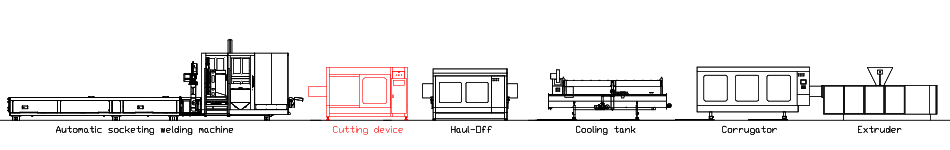

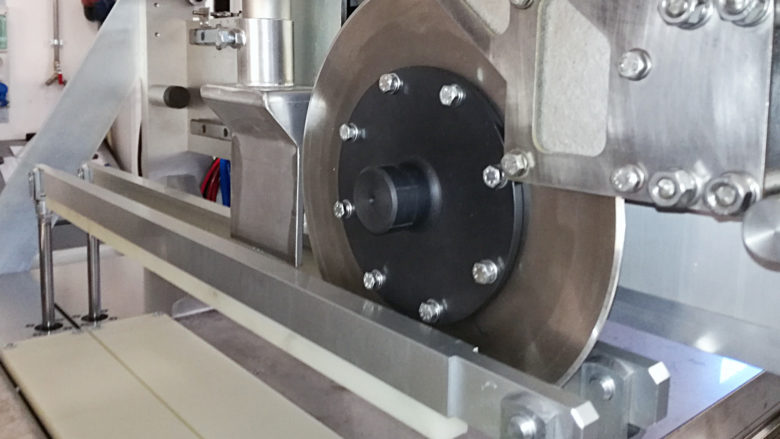

iCut is our new patented pipe cutting system that completely redefines the standard for high-quality pipe cutting. What differs from conventional pipe cutting systems is the absence of the planetary blade.

The heated blade moves along the axes through an independent mechanism powered by servomotors.

The advanced software allows iCut to simplify the whole process and makes it suitable to cut not only smooth or corrugated PVC, PE, PP pipes, but also profile geometries such as ovals, ellipses, rectangles, and irregular shapes.

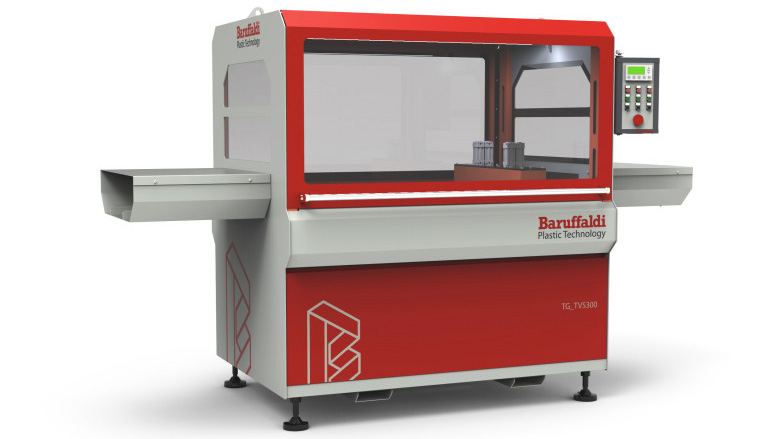

iCut is SMART

- versatile for pipes and profiles

- fast and precise

- quick set changeover

iCut is SAVING

- fewer moving parts

- lower maintenance

- less energy costs

iCut is SLIM

- less weight

- compact dimensions

- less noise

iCut is SUCCESSFUL

- increased speed

- cut quality and productivity