Milling Machines for extruded plastic profiles

Vertical Milling Machine: MM

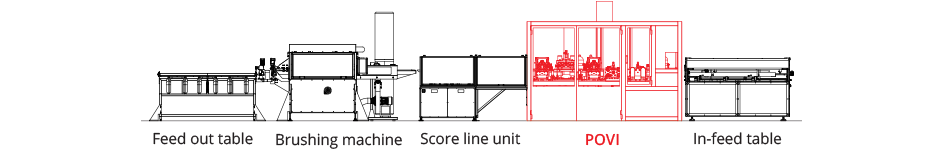

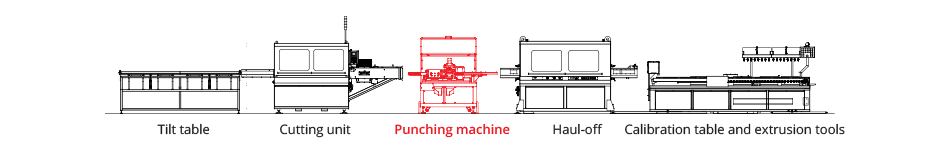

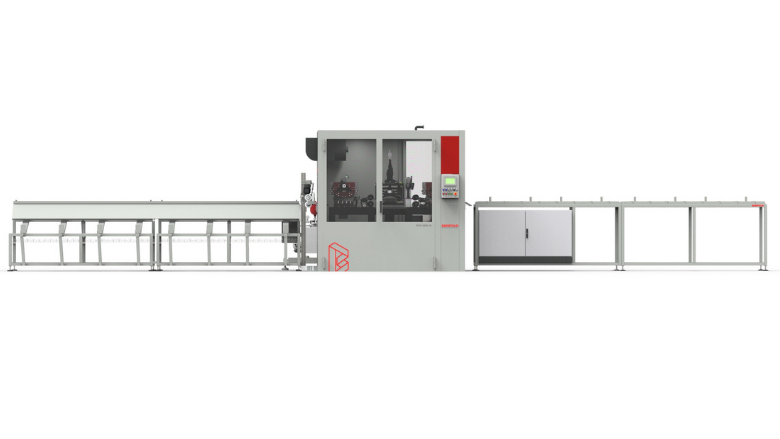

The technology applied to these automatic vertical milling machines is engineered for slotting double wall rigid PVC profiles of up to 600 mm in width, directly on the extrusion line.

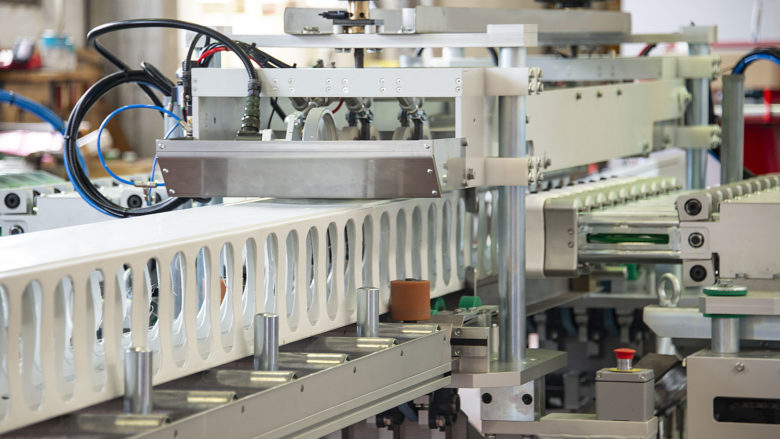

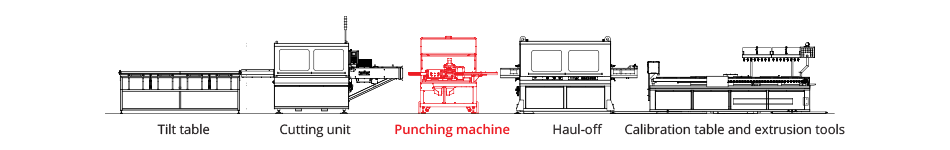

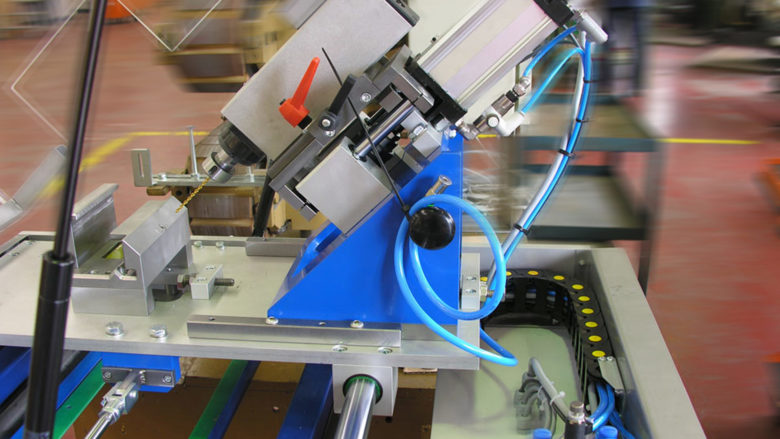

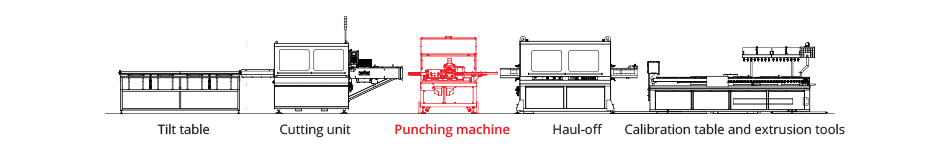

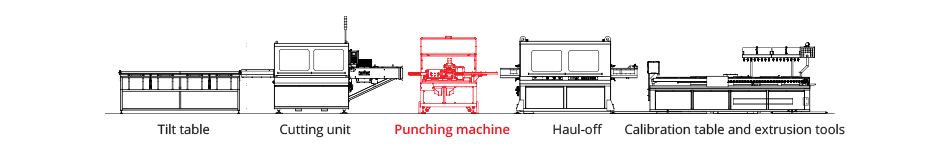

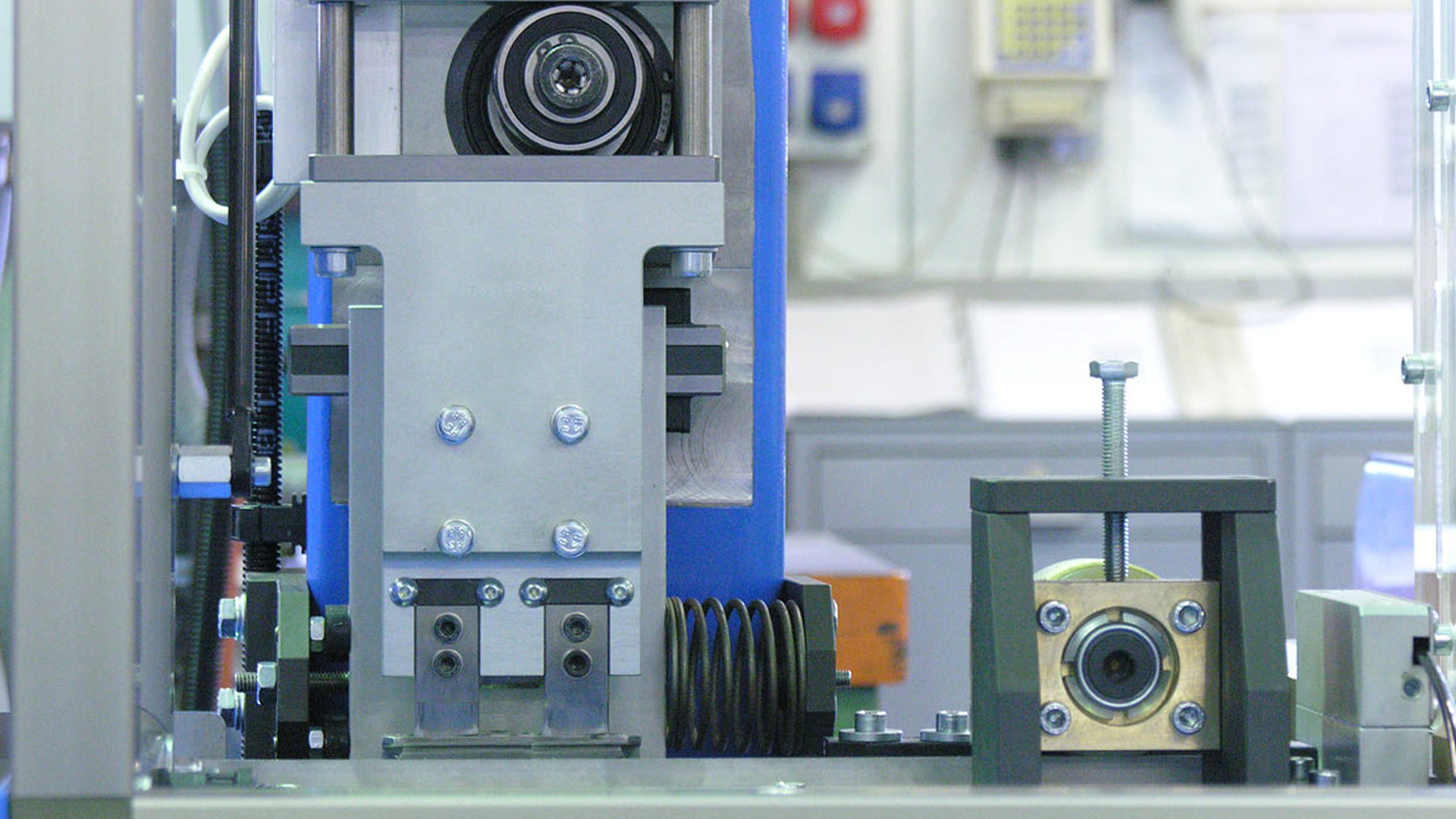

The machine is positioned between the haul-off and the guillotine and carries out the slotting process using a milling unit composed of independent modules mounted on a suitably dimensioned cooled bearing plate, which can house up to 44 milling tool holders.

The multiple milling head is mounted on columns and moves up and down to carry out the milling on the profiles. Carriage movement is controlled and driven by a brushless motor designed to synchronise the milling with the profile speed.

The machine is also equipped with an external suction unit to remove dust and milling swarf so that the profile is clean and ready for the next working process.

The choice of materials, such as the electro-welded box section steel, the painted frame, the anodised aluminium structures that support the moving parts, and the stainless steel used for parts in contact with the profile are all hallmark signs of a top-quality machine.

Applications

This type of machine finds its main application field in the extrusion industry of perforated double wall cable trays – For single wall ducts have a look at our punching machines!

The production of customised milling tools allows extremely precise and clean holes/slots. This machine is designed to be extremely versatile and manufactured according to different production needs. It can be used for different profiles formats and multiple drilling/milling patterns, for example, for double wall PVC cable trays.

Advantages

- High-quality milling and drilling process

- Highly versatile for different milling patterns

- Synchronisation between milling and profile speed

- Leading brand components

- Customised software upon customer needs

- Reliability and versatility of the milling process

- Easy use and quick milling tools changeover

Technical features

- Milling tool diameters from 5 mm upwards

- Speeds of up to 8 m/min

- System for heating the profiles (optional)

- Soundproof frame

- Scrap suction system

- Accident prevention devices

Horizontal milling machine: MILL8

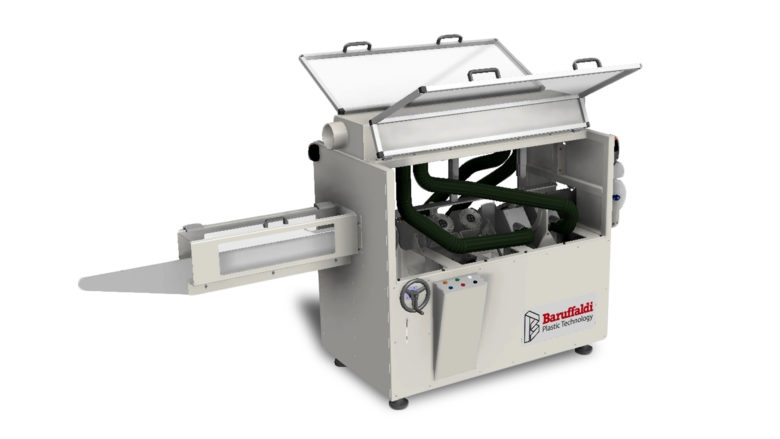

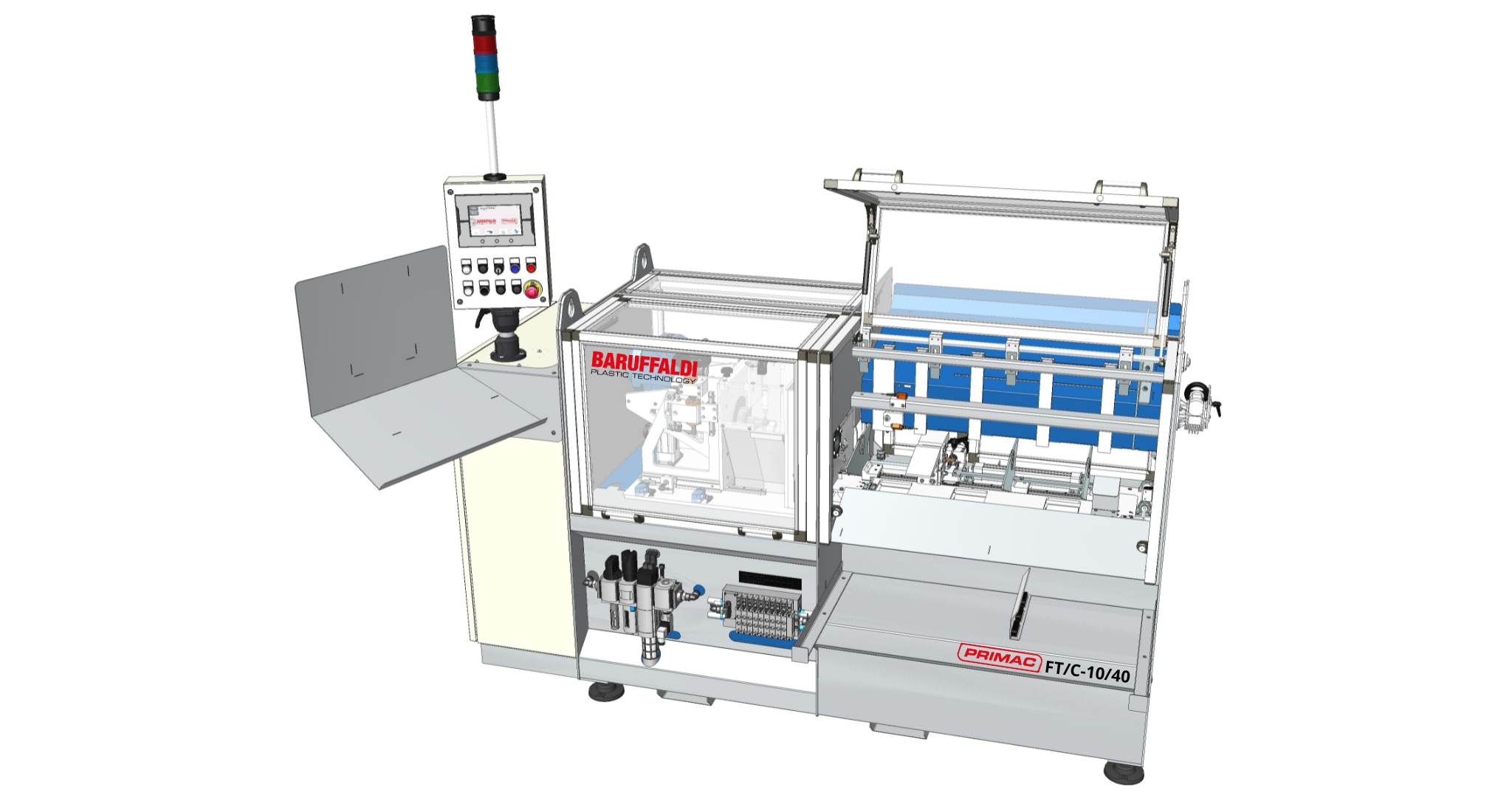

This machine reflects a new concept in modular milling systems to process large-scale multi-wall PVC profiles up to 355 mm in width.

Its modularity gives the possibility to add extra milling units, up to a max. of eight, depending on type of profile, extrusion speed or milling pattern. Moreover, Baruffaldi R&D department developed this new concept of a machine that can be used both in-line and off-line by adapting the thanks to its special software solution.

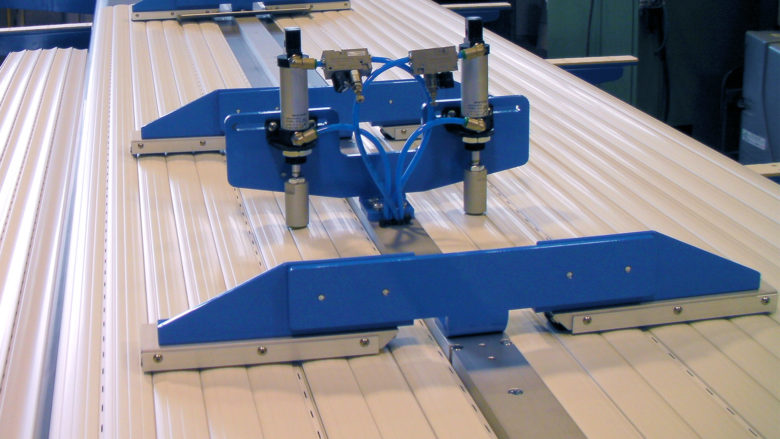

For the off-line use of the machine, both clamps are necessary: the infeed one, to be found at the machine entry, and the one placed on the carriage for the movement of the profile through the unit.

In the in-line use, the brushless motor (for the longitudinal movement of the carriage along the extrusion axis) and the encoder guarantee the perfect synchronisation of the carriage with the extrusion speed of the profile.

The milling unit makes round holes, all placed at the same distance one from the other, along the 6 profile walls, with the flexibility of managing different punching patterns, that can be set on the operator panel. The special milling tools complete with the related inserts are designed obtain a clean cut without burrs and minimise the material removed. The milling heads have a multiple movement that is repeated at each milling cycle: during their return stroke they hold the disk and release it at the end of the cycle.

The powerful aspiration system sucks the scraps of the milling process, while the milled disks fall into the special collection channels from where they are conveyed on the belt that drops them in the special container placed at the exit of the cabin, for the subsequent recycling.

Thanks to the Baruffaldi scrap-collection and recycling system, our milling machine MILL8 guarantees the cost reduction of the material used in production.

Scrap discharge belt and dust suction system

Baruffaldi always takes into consideration the need to safeguard a safe and healthy working environment. The two (inlet and outlet) tunnels and the soundproof safety cabin comply with the safety regulations, as the noise is much lower than the requirements of the current regulation on this issue. The MILL8 has a user-friendly operator panel and its routine maintenance is easy. Moreover, the remote assistance system allows Baruffaldi to give customers immediate assistance, as Baruffaldi is always on their side.

Advantages

- High-quality milling with no burrs

- Highly versatile for different milling patterns

- Off-line and in-line use

- Reliability and versatility of the milling process

- Leading brand components

- Reduction of production costs thanks to its high productivity and low maintenance costs

- Reduction of material costs thanks to the Baruffaldi scrap-collection and recycling system

- Modular milling units system according to required customer needs

- Easy use and quick size changeover

Technical features

- Dotazione da 2 a 8 moduli di fresatura indipendenti e sincronizzati

- Cabina di sicurezza insonorizzata

- Nastro trasportatore di evacuazione espulsione

- Software personalizzabile secondo le esigenze del cliente