In-line automated assembly machines for PVC roller shutters

COMBIROLL

We are automation equipment manufacturers and suppliers for the roller shutter industry.

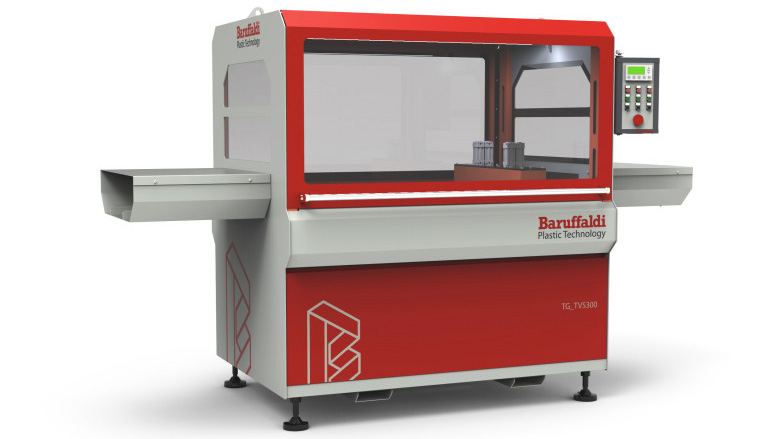

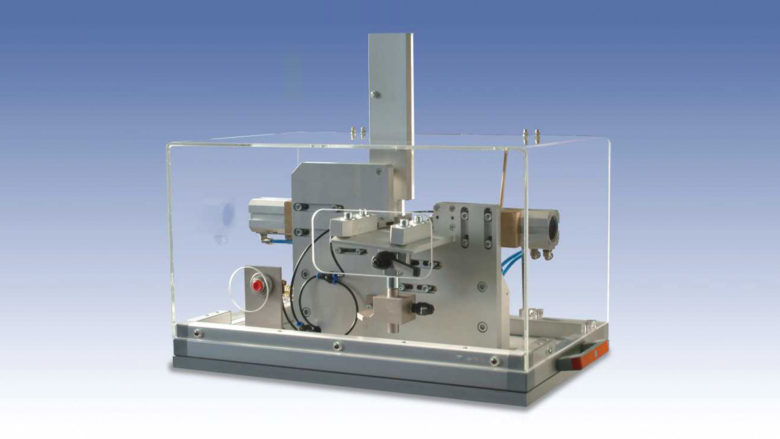

We provide special high productivity automated assembly machines dedicated to the production of PVC roller shutters in single and dual strand, directly in the extrusion line, with a productivity of up to 2 x 12 m/min, in case of dual strand extrusion. These are machines for assembly automation with punching, interlocking, cutting and assembly units. They are available in the pneumatic version and with brushless motors for high speeds.

The single units are equipped with the necessary accessories (punch tool sets, interlocking tool sets, and guillotine die blocks), designed and manufactured according to the customer’s roller shutter profile.

Advantages

- High precision cutting and punching up to 0.5 mm in the brushless version

- No dust, swarf, burrs on the extruded profiles

- Compact units

- Modular systems available with various types of interlocking systems

- Leading brand components

- Customised software according to the customer’s needs

- Process reliability

- Reduction of production costs

- Easy use and maintenance

Technical features

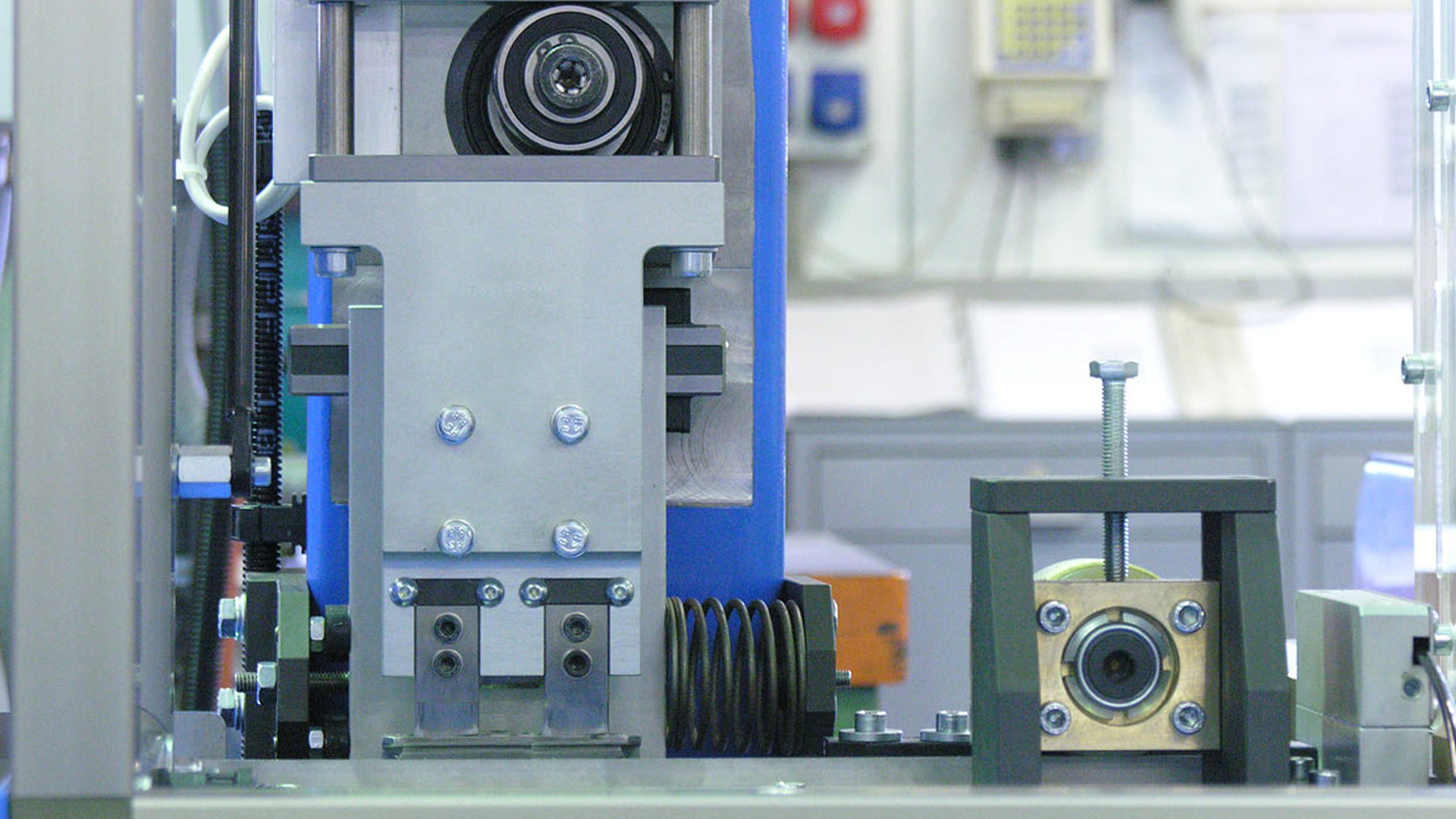

- Punching unit

- Guillotine cutting unit

- Interlocking units with notch or pin

- Assembly unit

- Automatic handling systems for the rolls (optional)

- Available in single and dual strand

- Available as pneumatic machines or with brushless motors, depending on the customer’s production requirements

- Intranet application to send production data directly to the machine

- Label bar-code scanner

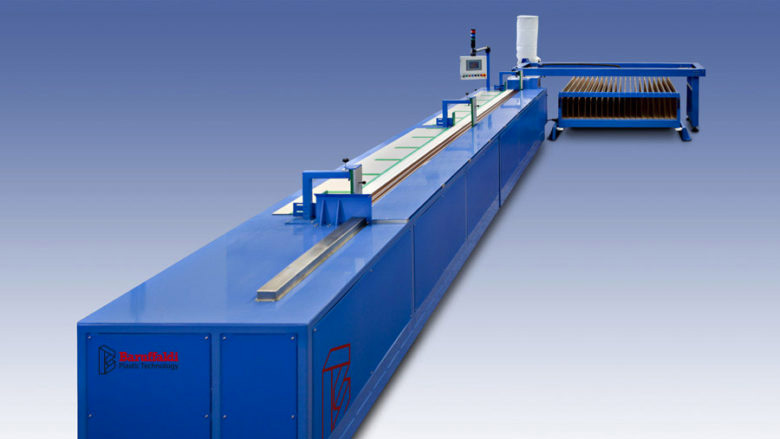

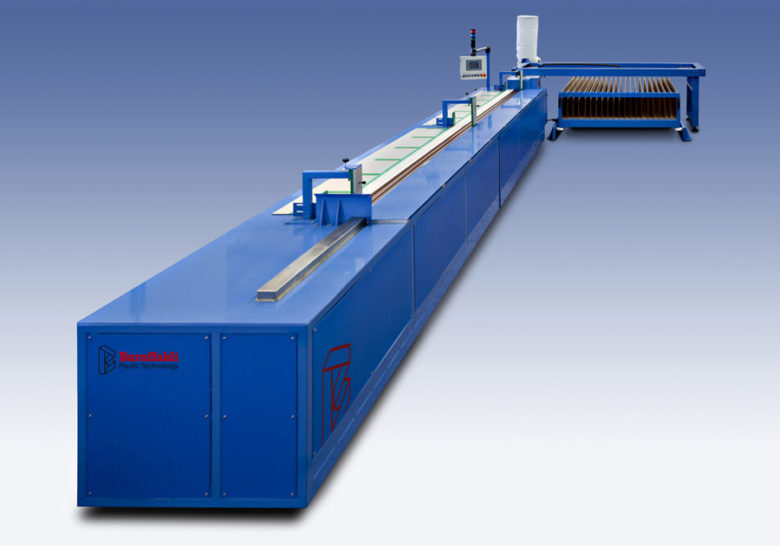

C1/TL-6 and C1/TL-10

With notch or pin interlocking system

Automatic roller shutter machines in a pneumatic version for an extrusion speed up to 6 m/min, or with brushless motors for a speed of up to 12 m/min.

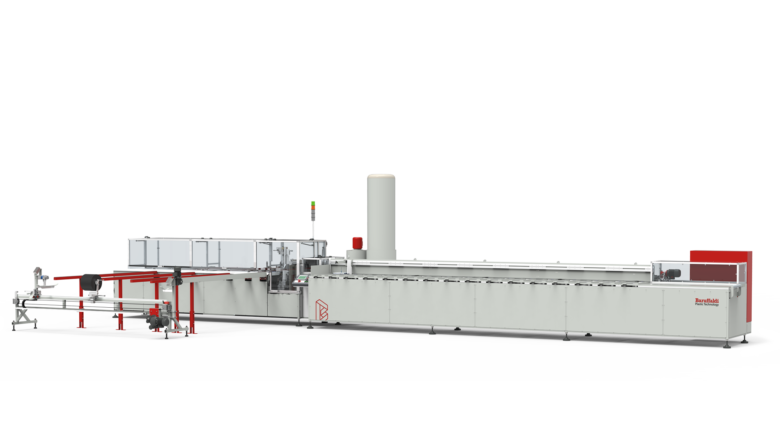

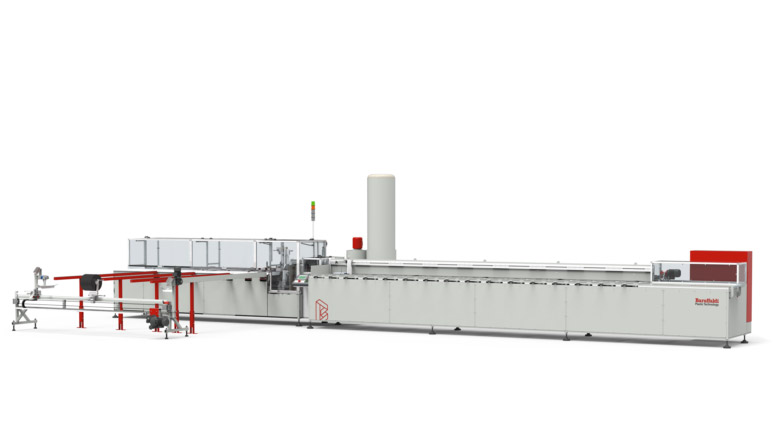

C2/TL-6 and C2/TL-10

With notch or pin interlocking system

Automatic roller shutter machines for dual strand extrusion lines. Available in a pneumatic version for an extrusion speed of up to 6 m/min, or with brushless motors for a speed of up to 12 m/min.

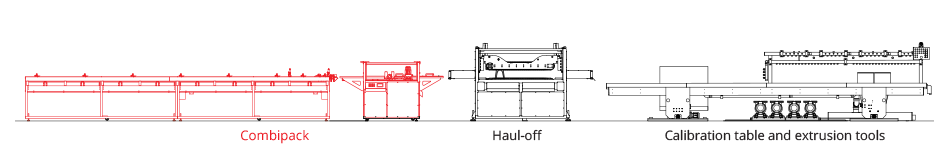

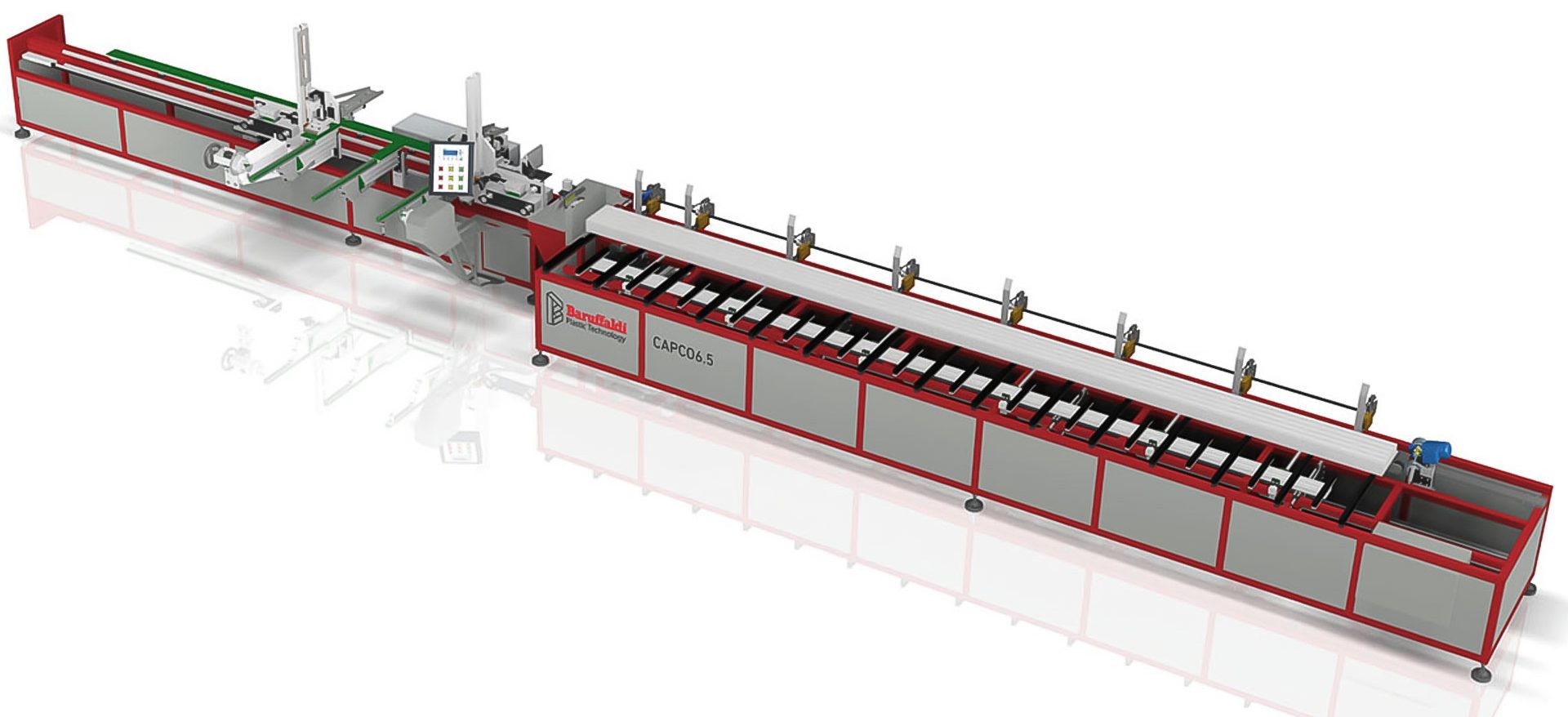

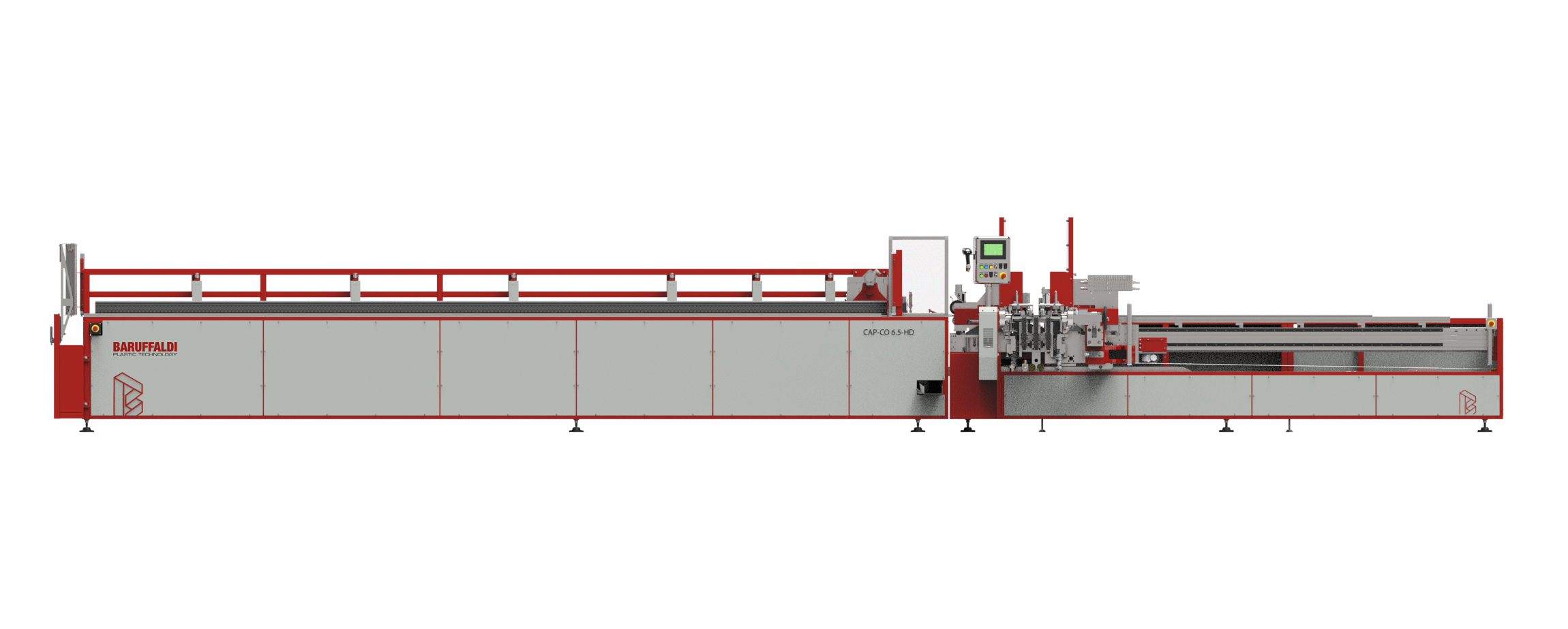

Combiroll-Pack

Automatic roller shutter machine for the simultaneous production of roller shutters and 6.5 m long slat packs. It is available as a pneumatic unit for an extrusion speed of 6 m/min and a servo-aided unit for 12 m/min extrusion speed.

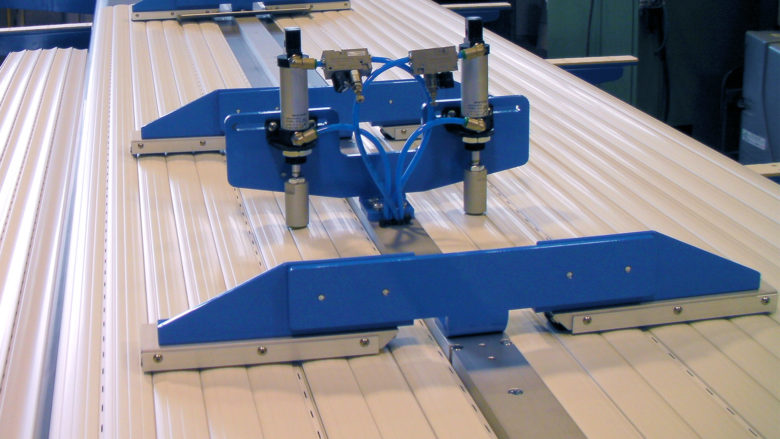

Its dedicated software allows the operator to switch production from roller shutters to slat packs easily and back again according to production needs. The Combiroll-Pack is equipped with two mechanically independent lines and an innovative system “that” includes extractable supports, tilt steel rollers and automatic mobile roller shutter supports.