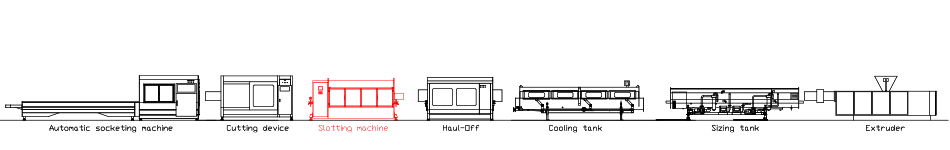

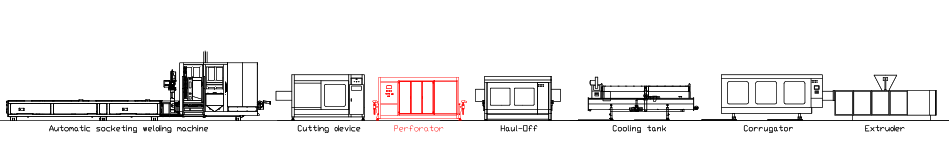

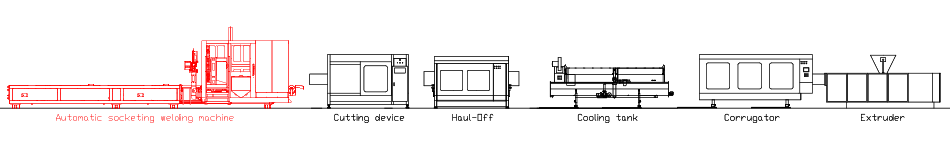

Primac downstream equipment for PTFE pipes

With more than 40 years of experience in the extrusion of plastic and high-temperature resistant materials, Primac technology in the manufacturing equipment and production lines for PTFE pipes. PTFE pipes are used for special applications: in the medical industry (i.e. to convey food fluids, etc.), and in the electronic and automotive industries. Baruffaldi-Primac know-how guarantees top quality standards of the final product, which makes it possible to obtain the certifications the market requires.

Our equipment for PTFE includes the following technologies:

- Unwinders for coiled pipes

- Special water calibration and cooling tanks

- Purpose-built haul-offs for thin-walled pipes

- Automatic winders to coil flexible pipes

- High-speed planetary cutters with a swarfless cutting system

- Laboratory machines to test pipe pressure and temperature resistance

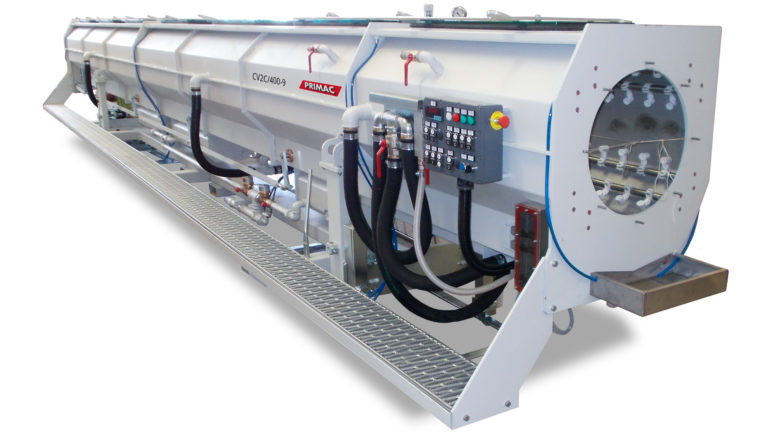

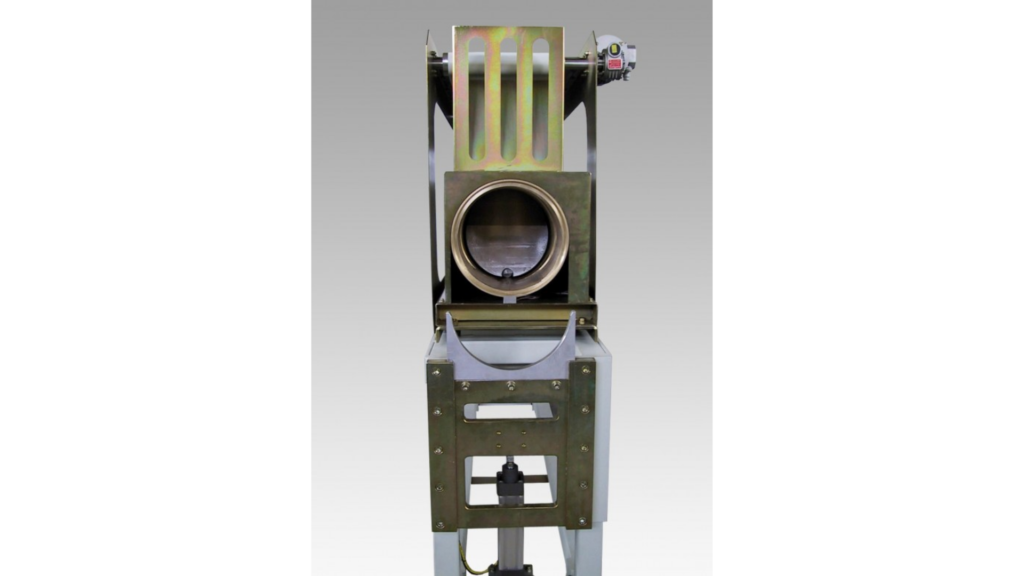

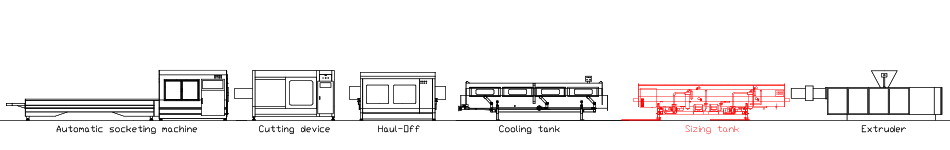

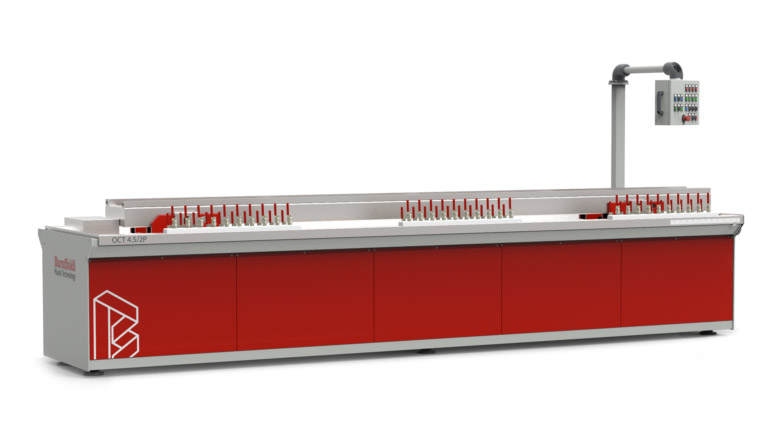

Calibration and Cooling Water Tank

Type CV/63-I-D

- 2 m length

- Pressure and vacuum regulation systems

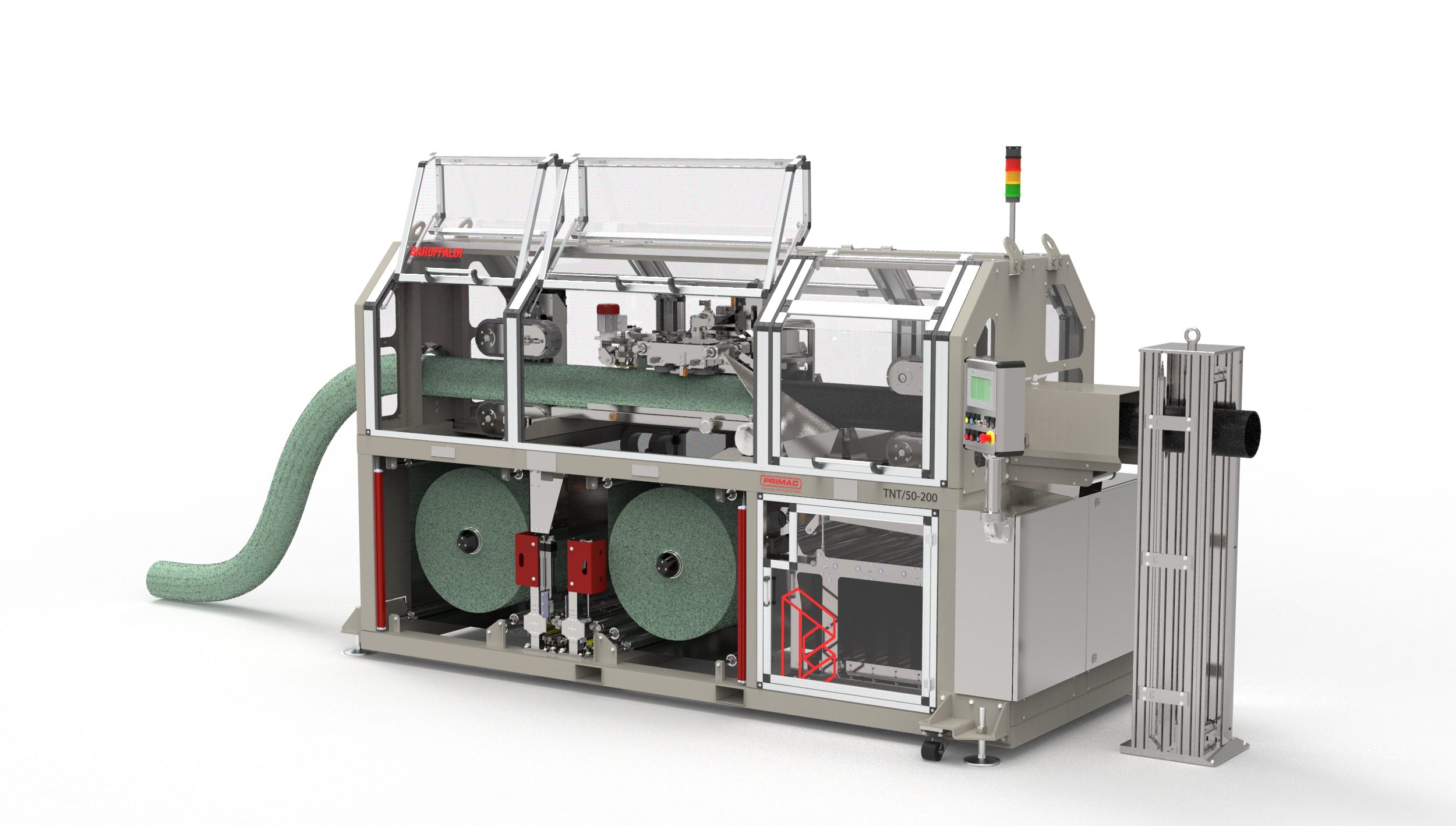

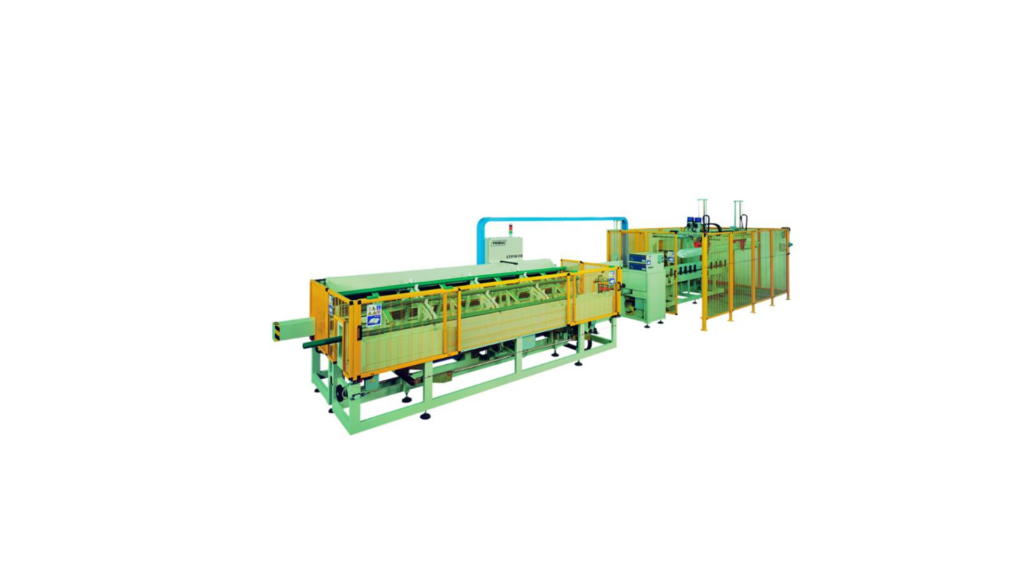

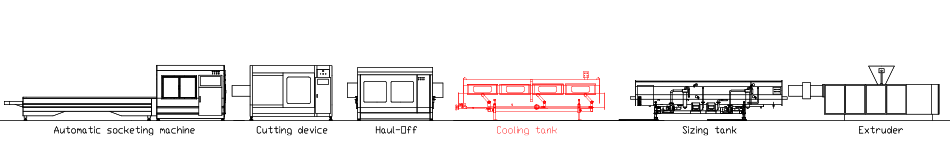

Haul-Off

Type T2C/63-V/D

- For thin-walled pipes from Ø 2 to Ø 20 mm

- High extrusion speed up to 20 m/min

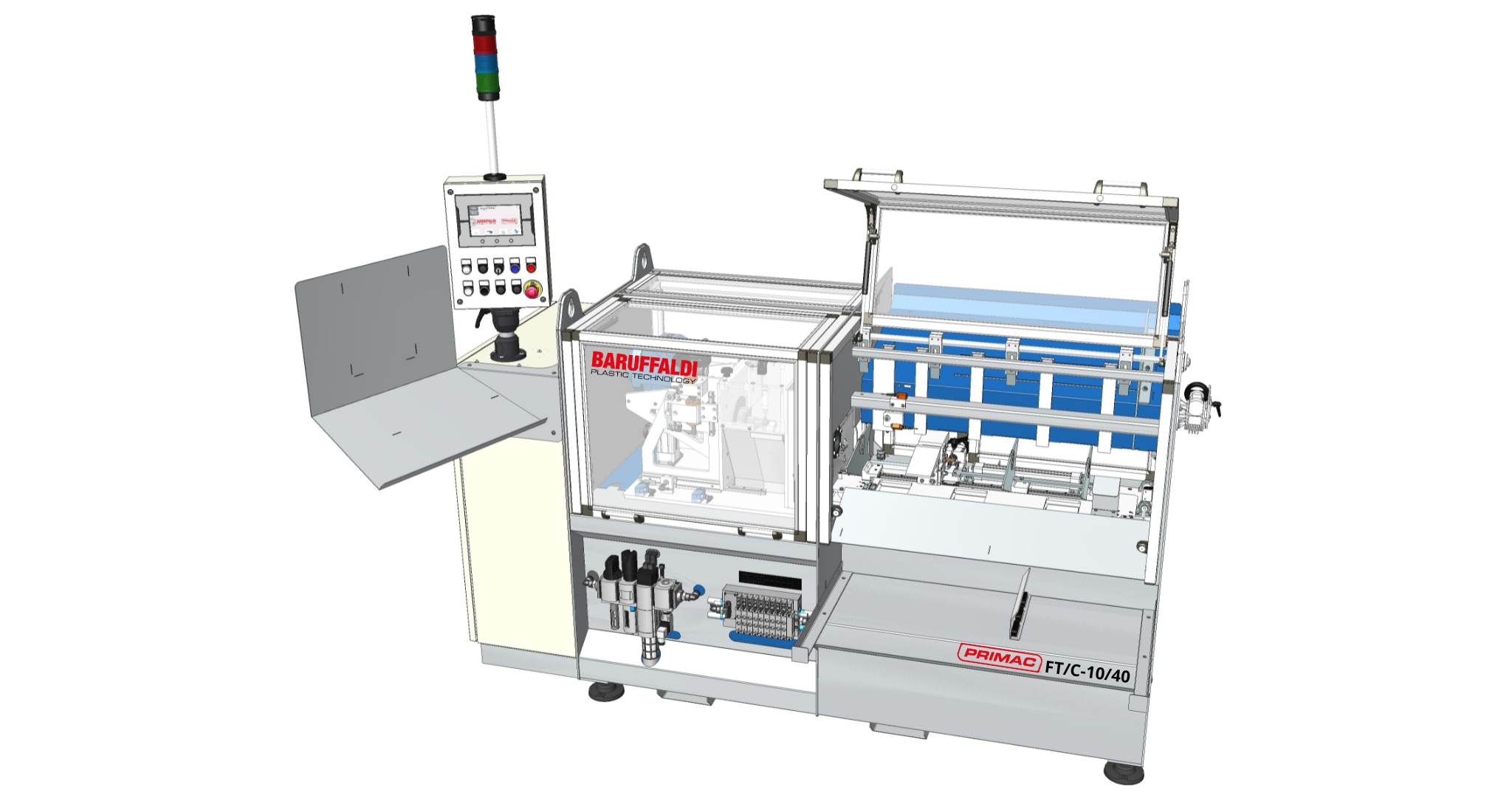

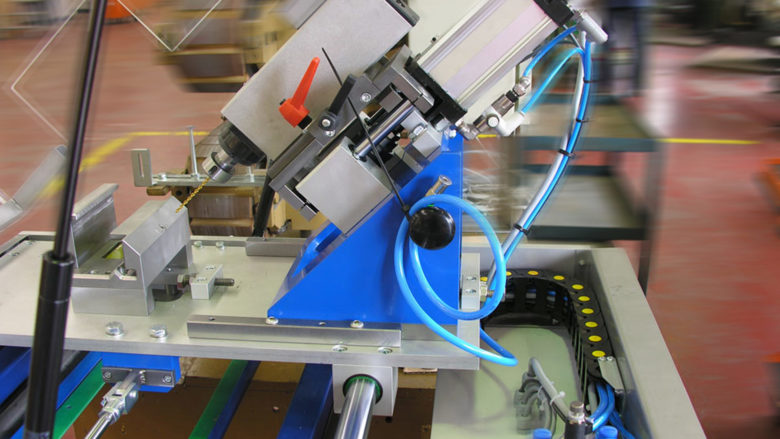

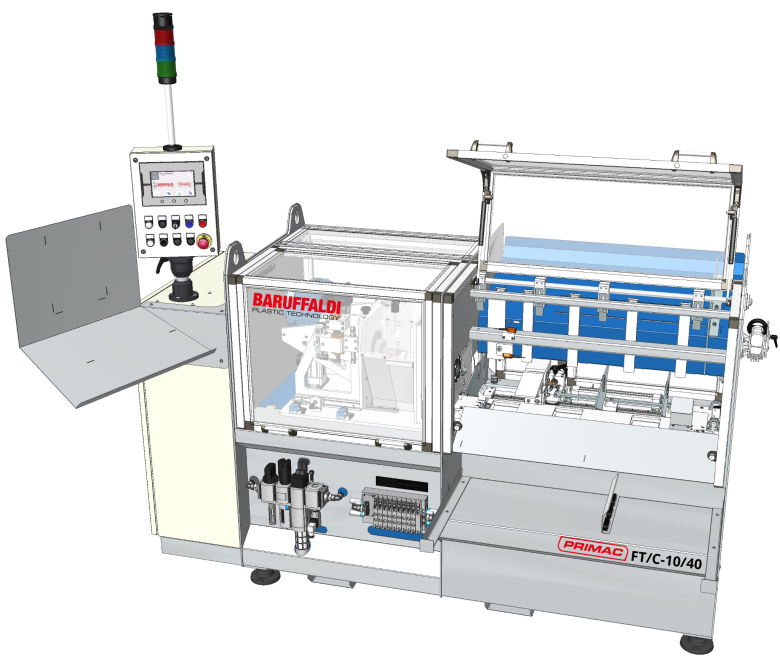

Planetary Cutting Machine with Compact Haul-off

Type T.T.V.P-AR/20

- Knife-cutting system with planetary movement of the blade

- Capable to cut 200 pieces/min

- Cut tolerance of ± 0,1 mm

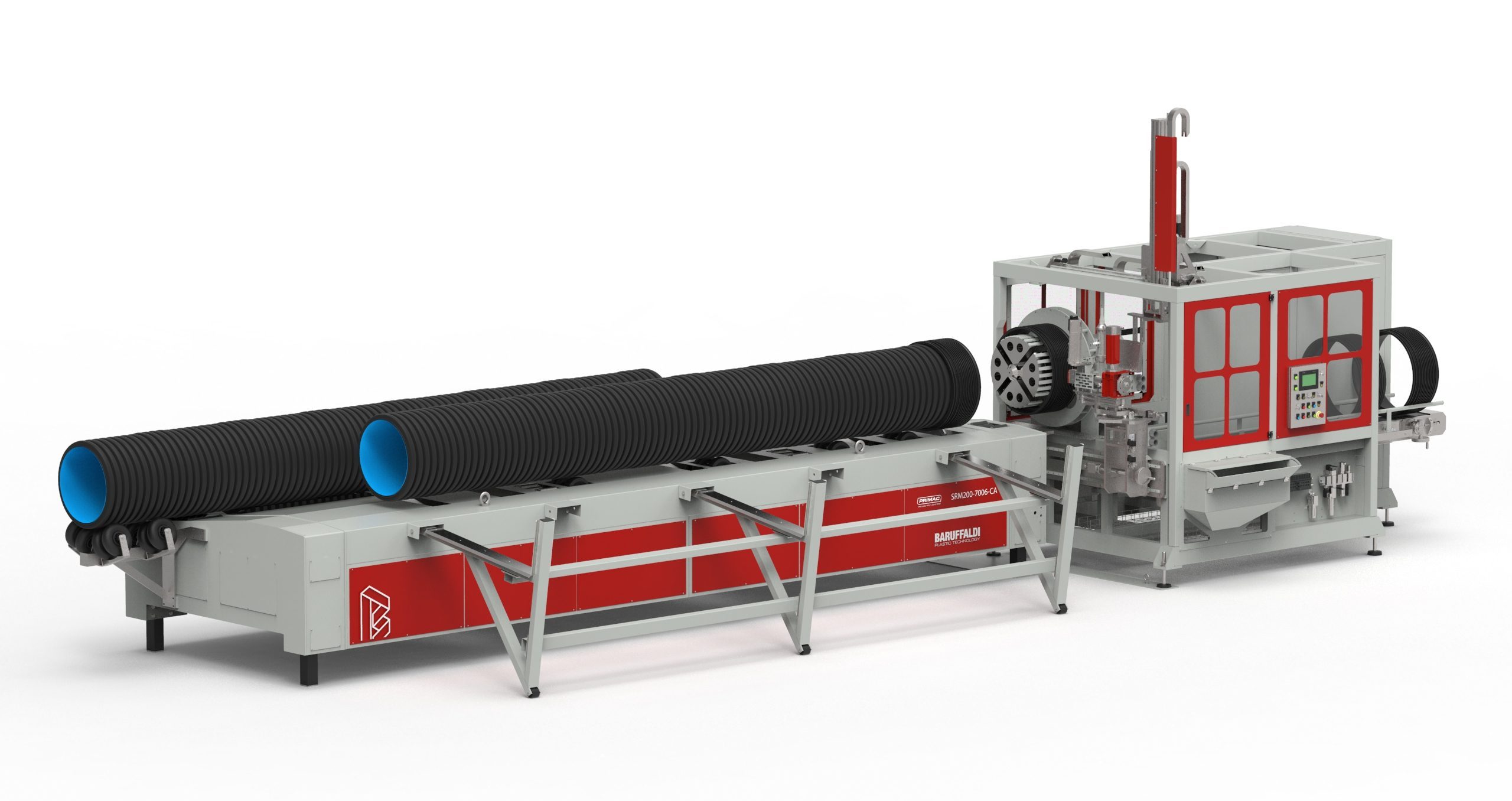

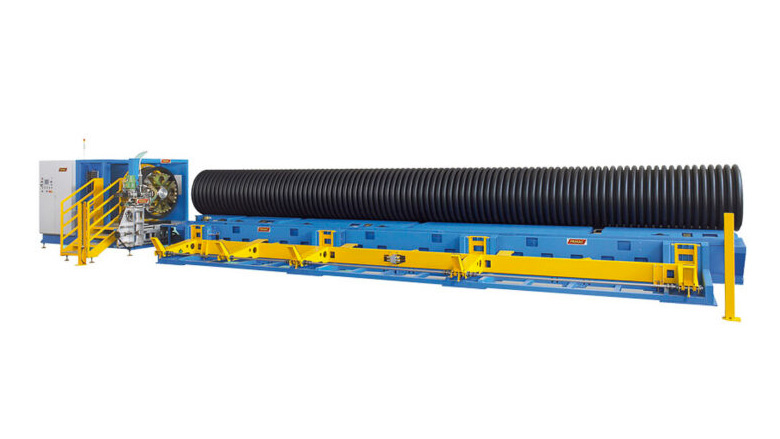

Automatic Winder

Type AV-A/2-D

- Winding unit to coil flexible pipes

- Pipe diameters from Ø 2 to Ø 30mm

Laboratory Testing Machines for Pipes

Type PCE/100

- Hydraulic pressure generator for pipe testing

- Pneumatic pressure generator for pipe testing