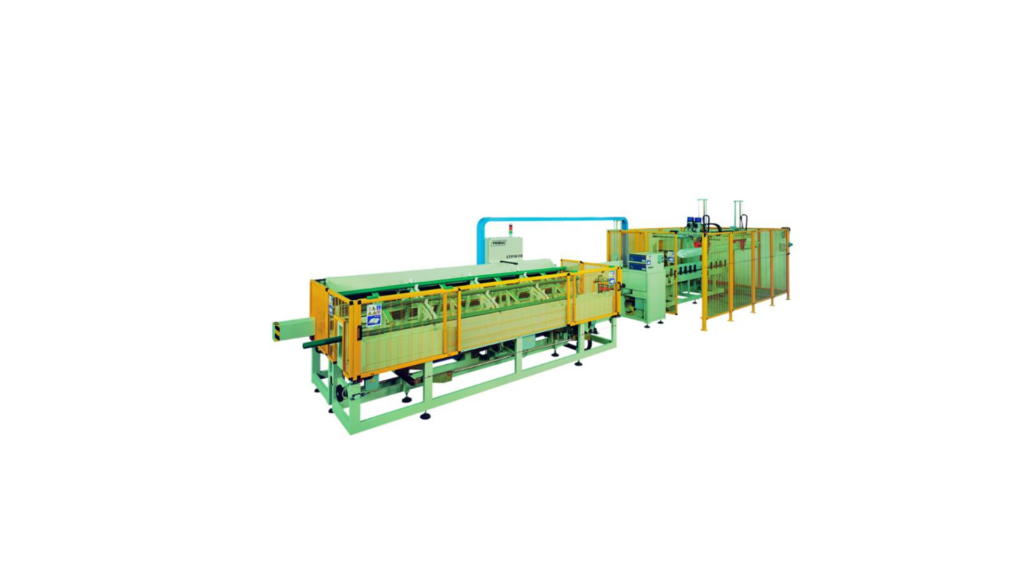

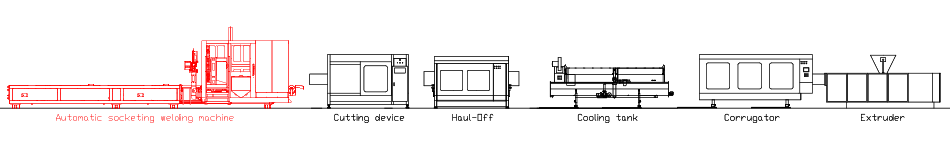

Socket welding machine for corrugated pipes

SRM

Automatic in-line machinery for the socket welding process of PE and PP corrugated pipes of between 110 and 1400 mm diameter.

Advantages

- No loss of speed on the extrusion line

- Reliable weld even after prolonged storage or incorrect pipe laying

- No production waste

- Maximum strength without problems of ovality

Technical features

- For standard length pipes 3, 6 or 12 m, without length limits

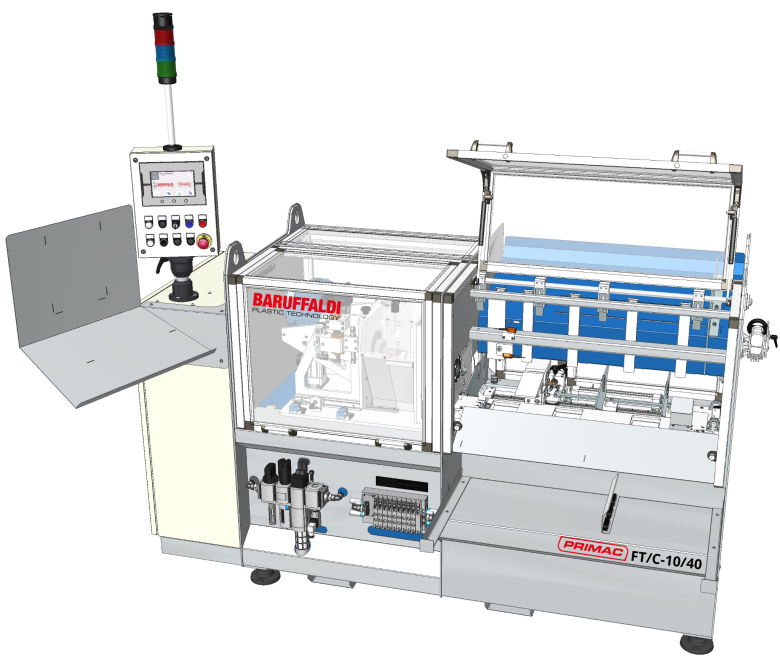

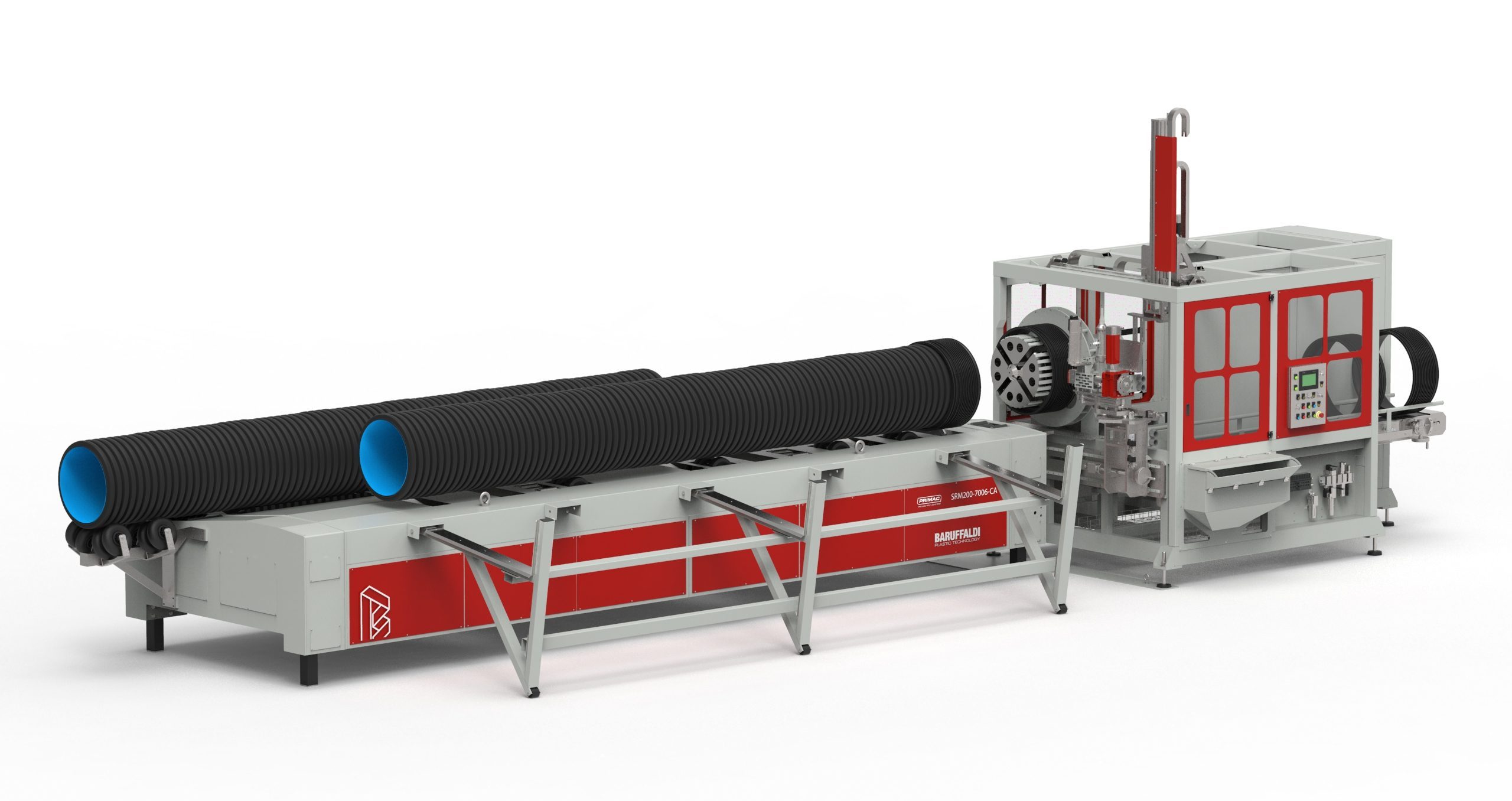

S.R.M.

PIPE-TO-SOCKET WELDING MACHINE

Automatic jointing of the socket to the pipe by means of a patented system of welding using added materials.

Options

- The socking itself can be cut in half to form two couplings

- Double weld bead is possible if desired

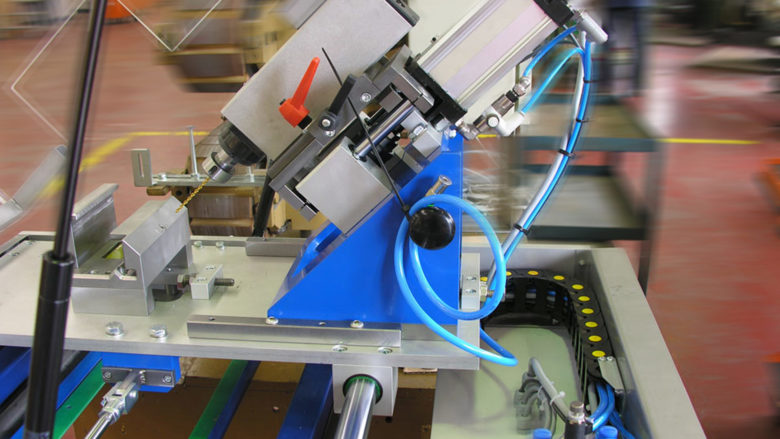

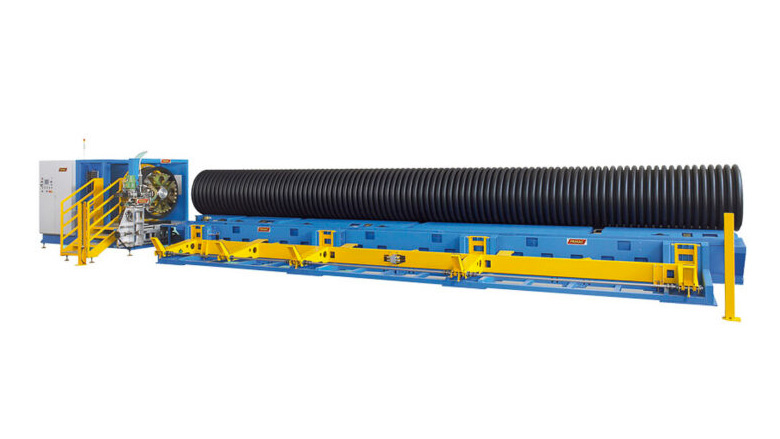

I.A.M.-S.

JOINTING BY SOCKET FRICTION WELDING MACHINE

Automatic fitting of the socket by means of fusion welding and automatic weld testing.

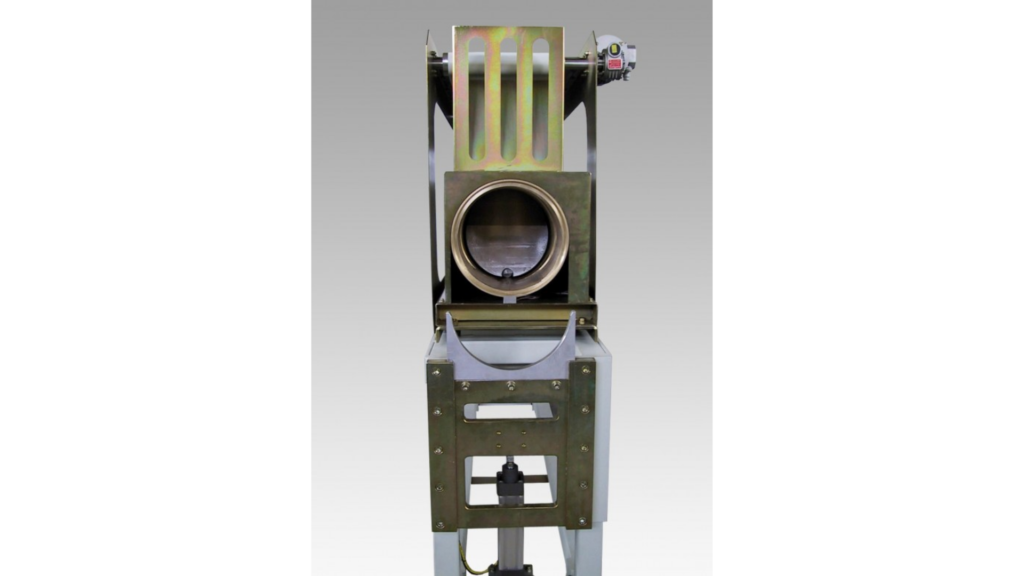

I.A.M./I.A.G.

AUTOMATIC PIPE SEAL AND SOCKET ASSEMBLY MACHINE

Automatic fitting of the socket by means of fusion welding and automatic weld testing.