- Baruffaldi profile extrusion technology

Profile Extrusion Technology

- Primac pipe extrusion technology

Pipe Extrusion Technology

- Company

- Services

- News

- Events

- Contact us

- Log In

Specifically designed for the off-line automated assembly of aluminium and steel roller shutters. It can process slats between 500 and 6500 mm in length. Once they have been inserted at both ends, the plastic caps are fixed into the profile by means of metal clips (single or double) or with a punching system (from above or from below). The same system can also be used to assemble PVC roller shutter profiles for swimming pool covers.

With the basic version, CAP-ST, it is possible to automatize the phases of the insertion and fixing of the caps into the roller shutters, the operator has already manually pre-assembled.

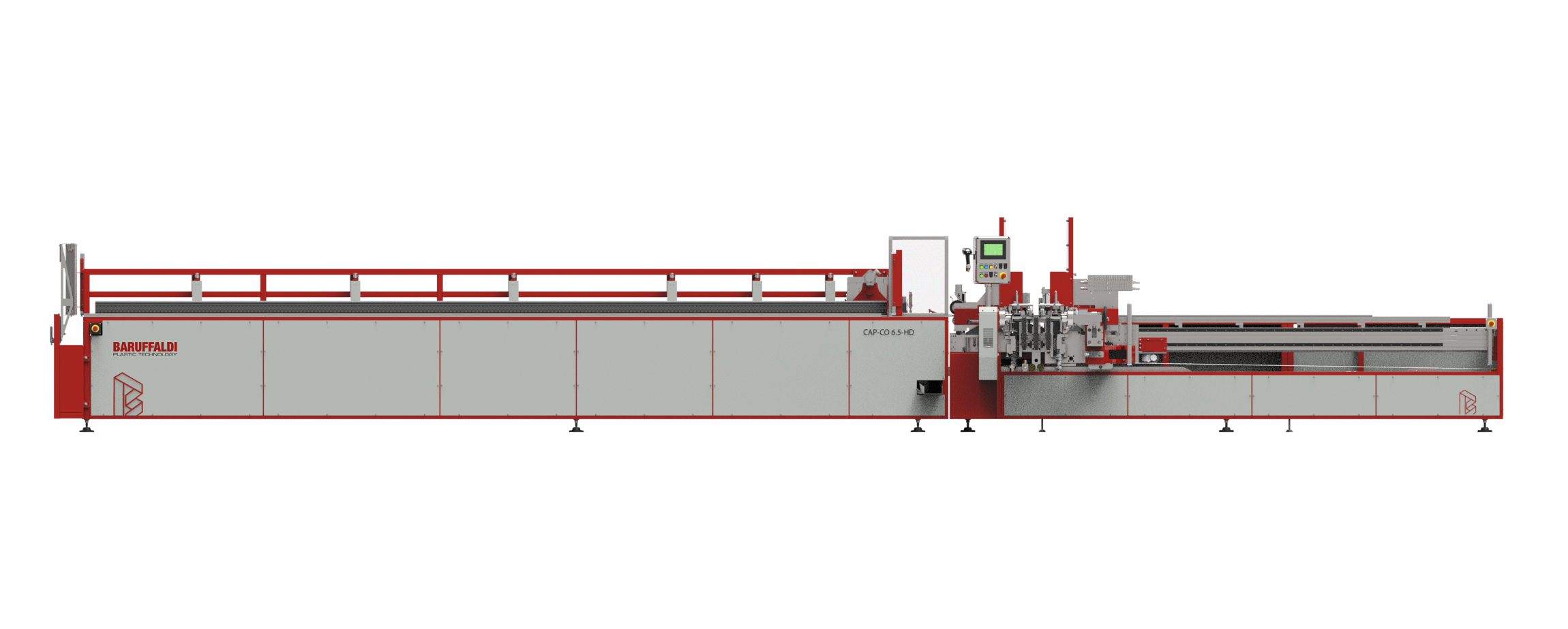

The machine can be equipped with a vertical feed-in table (CAP-CV), for profiles already cut to length, or with horizontal one (CAP-CO) for pre-assembled slat packs. Thanks to our modular system it is possible to design different plant versions according to the customer’s needs.

To the basic version it is possible to add: a cutting device to cut to length the roller shutter profiles, a punching unit to punch the profiles and a motorized unit or a standard semi-automatic unit rolling up unit to roll up the finished roller shutter.

The CAP-CO version is also available with an inserter for packs of 4 slat packs for high production speeds. Thanks to this special inserter, the machine can insert packs of 3/4 slats at a time, speeding up the process. With this machine it is possible to produce one m² in about one minute *.

The software has been studied and designed to assembly roller shutters of any length, inserting even more programs at a time, the metal terminal at the end of the roller shutter and the intermediate bolt. In addition, the cap inserter can be equipped with a scanner for barcode reading and automatic production data entry.

Upon customer’s request, we can also supply independent vibrating bowl feeders for the automatic insertion of the caps inside specific guides, which facilitate their feeding into the cap inserter feed-in table.

All our Cap Inserters can be equipped with an additional unit specifically designed by Baruffaldi for the creation of the space for the cap in high-density polyurethane foam. This unit has been specifically studied and designed to create the necessary space for the cap, in all profiles sizes. Baruffaldi gives the customer the possibility, with a single machine, to assemble roller shutters with slats of all sizes (both mini and maxi) and with both low and high density PU.

* purely indicative data, which varies according to the size and geometry of the profile.