- Baruffaldi profile extrusion technology

Profile Extrusion Technology

- Primac pipe extrusion technology

Pipe Extrusion Technology

- Company

- Services

- News

- Events

- Contact us

- Log In

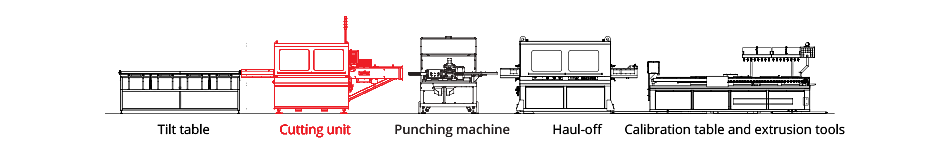

This type of machine applies state-of-the-art technology to the longitudinal cutting, of PVC foam boards, extruded in single or dual strand, honeycomb rigid PVC panels and flat “sandwich” plastic panels in general, directly in the extrusion line, without making any dust or swarf.

The units for the longitudinal cut (SM/L versions for cutting thickness up to 10 mm or up to 25 mm) and transversal cut (SM/T version), can be used individually or even in combination with each other, depending on the production requirements.

In-line cutting occurs at a high speed, which reaches up to 8 m/min. Moreover, thanks to the pneumatic adjustment of the blade in height, it is possible to quickly adapt the machine setting to the extruded product.

Available in versions with one, two or three cutting heads, they allow longitudinally cutting of 1500 mm wide panels. The position of the cut assembly can be set according to the desired width by means of a manual or motorized (optional) adjustment of the heads.

This technology is particularly suitable for cutting PVC foam boards, extruded in single or dual strand, rigid PVC honeycomb profiles and even “sandwich” type plastic panels, without making any dust or swarf.

The version for transversal cutting, the SM/T, suited to the in-line cutting of ceiling and wall cladding panels, extruded in single or dual strand, or honeycomb panels, and has a working range of up to 850 mm in the (standard version). The blade rotation is motor-driven, to guarantee an efficient cutting process.

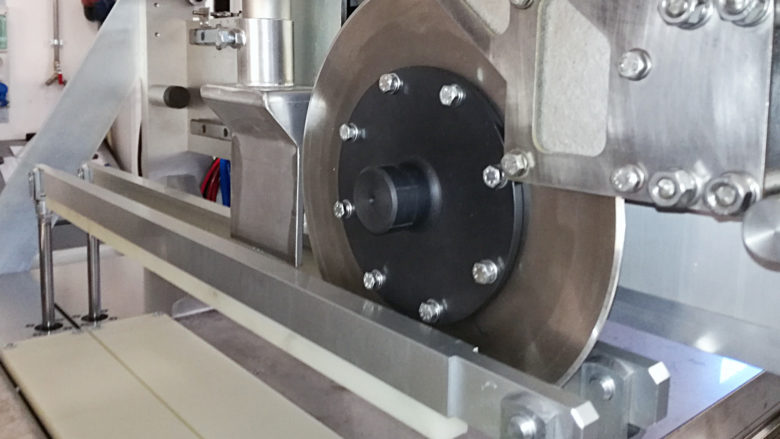

In both versions, there is the option of fitting an electrical heater to preheat the panel to facilitate cutting and optimise machine performance. The frame made of painted, electro-welded box section steel, the structures supporting the moving parts in anodised aluminium and the parts in contact with the profile in stainless steel all makes this a top-quality machine.