- Baruffaldi profile extrusion technology

Profile Extrusion Technology

- Primac pipe extrusion technology

Pipe Extrusion Technology

- Company

- Services

- News

- Events

- Contact us

- Log In

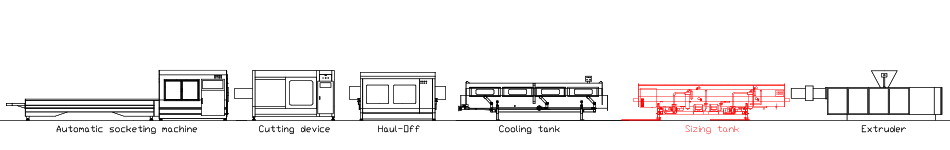

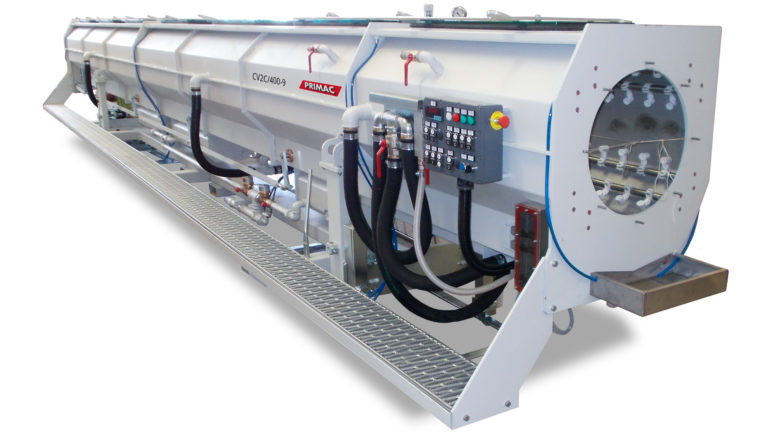

Dual or single vacuum chamber sizing tanks for pipes extrusion with a diameter range of between 10 to 1000 mm, in single or dual strand.

The sizing tanks are made of stainless steel and are fixed to a steel base, equipped with independent automatic or manual devices for longitudinal and transversal position adjustment on the extrusion line.

The machines are equipped with a water system with thermostatic and valve controls to reduce the amount of water in circulation and keep the cooling temperature constant.

Water is pressure-sprayed onto the pipe by spray sprinklers assembled on stainless steel bars; the spray angle is adjustable. Spray water is recycled and cleaned through a filter, thus preventing clogging of the sprinklers.

An electric motor, connected to a rail fixed to the floor, controls longitudinal movements.

Supplied on request according to production requirements: