- Baruffaldi profile extrusion technology

Profile Extrusion Technology

- Primac pipe extrusion technology

Pipe Extrusion Technology

- Company

- Services

- News

- Events

- Contact us

- Log In

The hydraulic cable duct punching machines POVI 10000 and POVI 5000 are the only plants in the world designed to reach process speeds of up to 12 m/min. with the highest quality standards.

They are designed and manufactured to produce PVC and PC/ABS electrical cable ducts and trunkings according to the standard punching patterns required by the market.

POVI 10000 and POVI 5000 are modular systems that can be customized according to the customer’s specific production needs. Baruffaldi Plastic Technology is the only partner capable of designing and manufacturing the most suitable plant to secure the maximum capital return on your investment.

POVI 10000 and POVI 5000 are off-line state-of-the-art high-productivity systems, designed to punch and coin cable ducts and trunkings on three sides.

It is possible to punch all sizes with the same plant: from the smallest one (15×15 mm) to the biggest one (100×150 mm). The punching process can also be combined with the so-called embossing process, which consists of making a “fingerprint” on the outer profile surface, facilitating manual removal of the pre-punched part during installation.

Coining is a special technology developed exclusively by Baruffaldi, that adds an important plus to the product, eliminating swarf and sharp edges caused by the punching process on the cable duct sidewalls.

Moreover, POVI 10000 and POVI 5000 are equipped with an innovative cable duct transport system inside the various units of the plant, which leaves no visible mark on the bottom of the duct.

The POVI 5000 has a lower cost, both in terms of investment and maintenance, but guarantees the same quality as the POVI 10000 thanks to the same technical characteristics of these off-line punching and coining machine.

The soundproof cabin guarantees low noise levels and a reduction of acoustic emissions for a safe and healthy working environment.

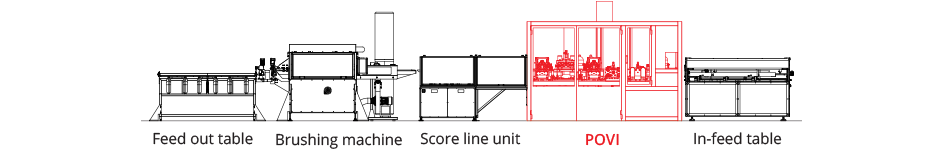

Frame with motorized height adjustment, manageable by two buttons and numeric display, with conveyor belt feeding table for the manual operator loading of the cable ducts.

A special device inserts the ducts one by one in the punching machine and the profile presence sensors verify the alignment with the axis of the machine, to avoid jamming.

The feed-in table is also equipped with a special unit to heat ducts feet, in case of high product thickness or low ambient temperature, in order to avoid breaking them during the punching process. The temperature is set according to the thickness of the product to be processed and the ambient temperature.

Independent, stand-alone unit positioned at the exit of the punching machine and before the feed-out table, complete with motorized devices for the advancement of the duct at a constant speed and its expulsion on the feed-out table at the end of the process.

In the standard version, the unit makes two continuous incisions (score lines) on each internal sidewall, one at the base of the slots and the other at the base of the wall respectively to facilitate the breaking of the fingers and of the sidewall itself. Position and depth of the score lines are easily adjustable based on the size and thickness of the cable duct.

All POVI systems can include a cable duct printing system to print the necessary production data on the product. Depending on the customer’s request, we can therefore include an inkjet printer, a laser printer or any other marking device chosen by the customer (optional).

Independent unit for applying 1 or 2 strips (depending on the cable duct width) of double-sided tape on the outside of the cable duct bottom.

The unit is positioned between the score line unit and the brushing machine and is equipped with 2 indipendent drive groups and cutting device to ensure correct handling of the products.

The POVI systems guarantee a high-quality punching and coining process, that normally leaves no residual burrs. However, in some cases (particular materials, critical geometries and complex punching schemes), it may be necessary to brush the “critical” area of the product, that is the feet. For this purpose, we therefore designed ad hoc brushing machines, which have the same characteristics of versatility and flexibility as the other units of the plant.

Our standard cable duct brushing machine consists of 2 heads, each equipped with 2 motorized brushes, with independent width, height, and inclination adjustment. The special carters positioned above the brushes can convey the dust to the suction device of the unit or the centralized suction system of the customer’s shop floor.

Solid and sturdy unit with adjustable feet, complete with extraction device and tilting supporting surface, pneumatically operated. The operator can easily pick up the cable ducts and place them in cardboard boxes or transfer them into containers. It is available in two standard lengths.

For customers who wish a different solution, we can also manufacture a horizontal out table with conveyor belts (size approx. 2 x 2.5 m) with a pneumatic device to release the punched and coined cable ducts on underlying belts.

An automatic unit with two octagonal axes deposits the cable ducts in an orderly manner on a pallet or inside special boxes. Customizable system based on customer needs.