- Baruffaldi profile extrusion technology

Profile Extrusion Technology

- Primac pipe extrusion technology

Pipe Extrusion Technology

- Company

- Services

- News

- Events

- Contact us

- Log In

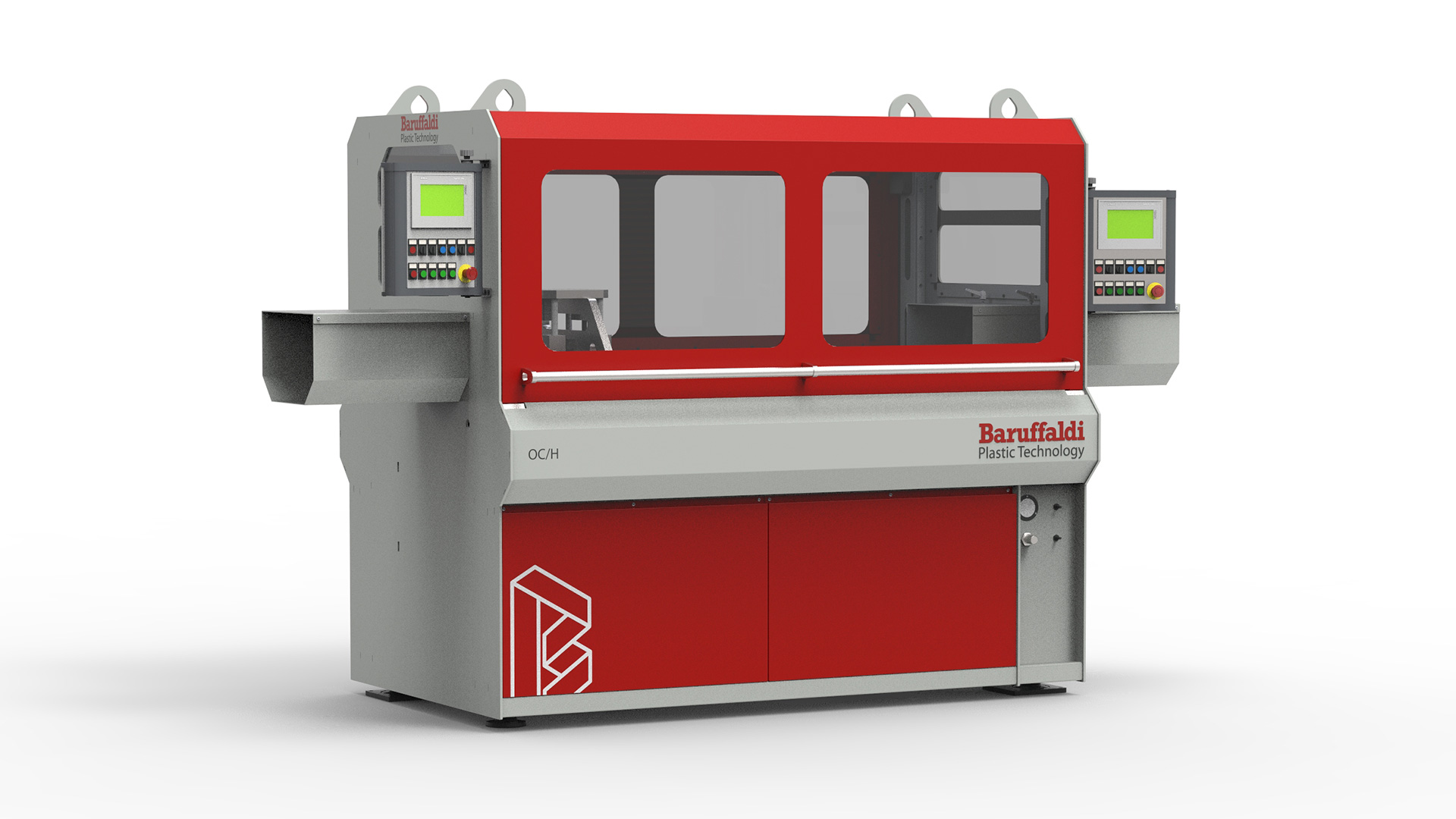

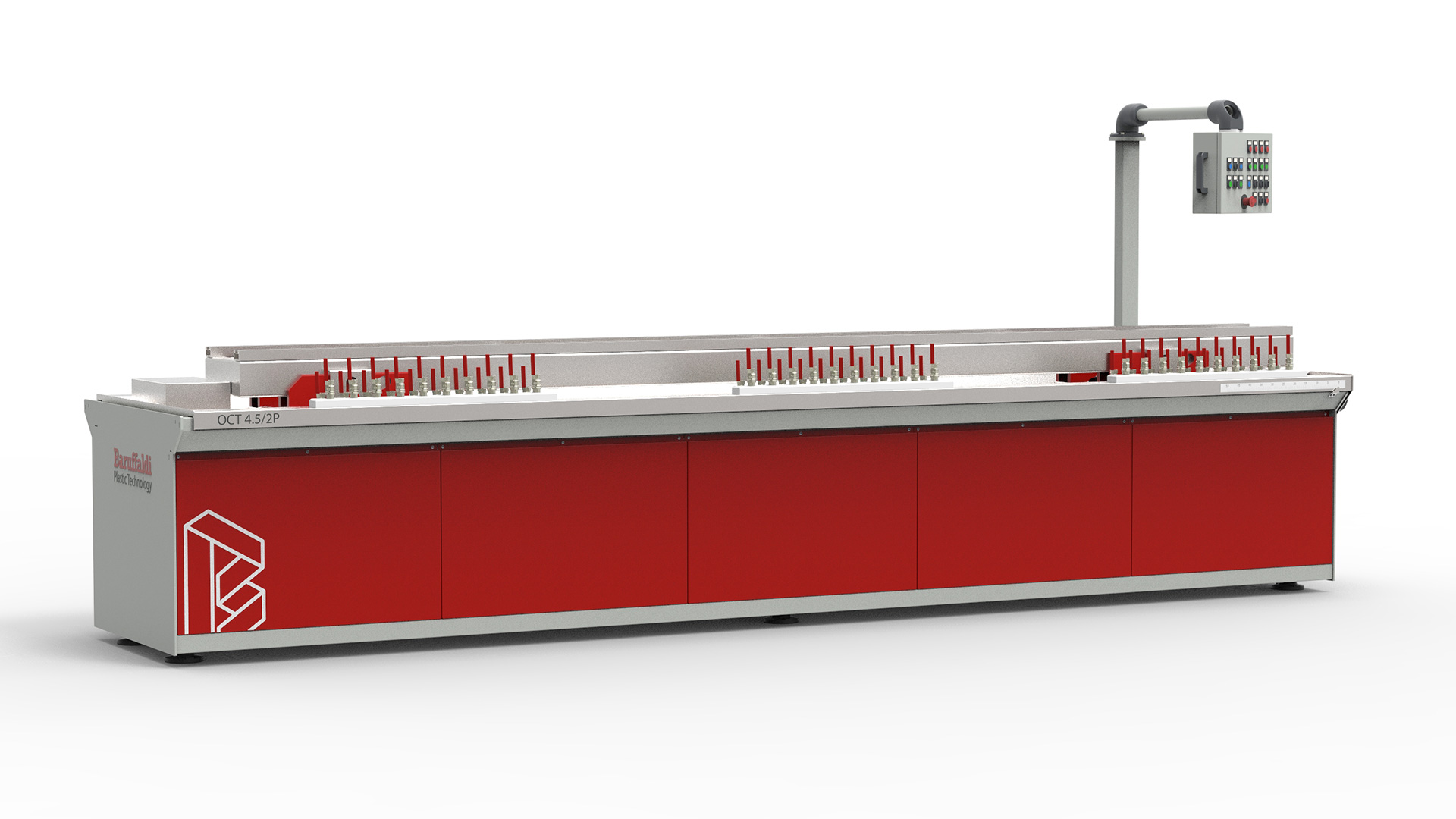

Single screw extruder mounted on a machine bed made of sectional steel and steel plate. It is available with a 45 mm, 60 mm, 75 mm or 90 mm diameter plastification screw made of normalized, hardened and tempered steel that can be fitted with a temperature control system and a nitrided steel cylinder with 4 independent temperature control zones.

The extruder is also available with different length/diameter ratios.

Omnia can also be used for the extrusion of pipes up to Ø 63 mm by mounting our sizing tank on the calibration table.

The quick-change pads allow the user to fit different types of rubber or contoured pads or to carry out maintenance with a generous time saving.