- Baruffaldi profile extrusion technology

Profile Extrusion Technology

- Primac pipe extrusion technology

Pipe Extrusion Technology

- Company

- Services

- News

- Events

- Contact us

- Log In

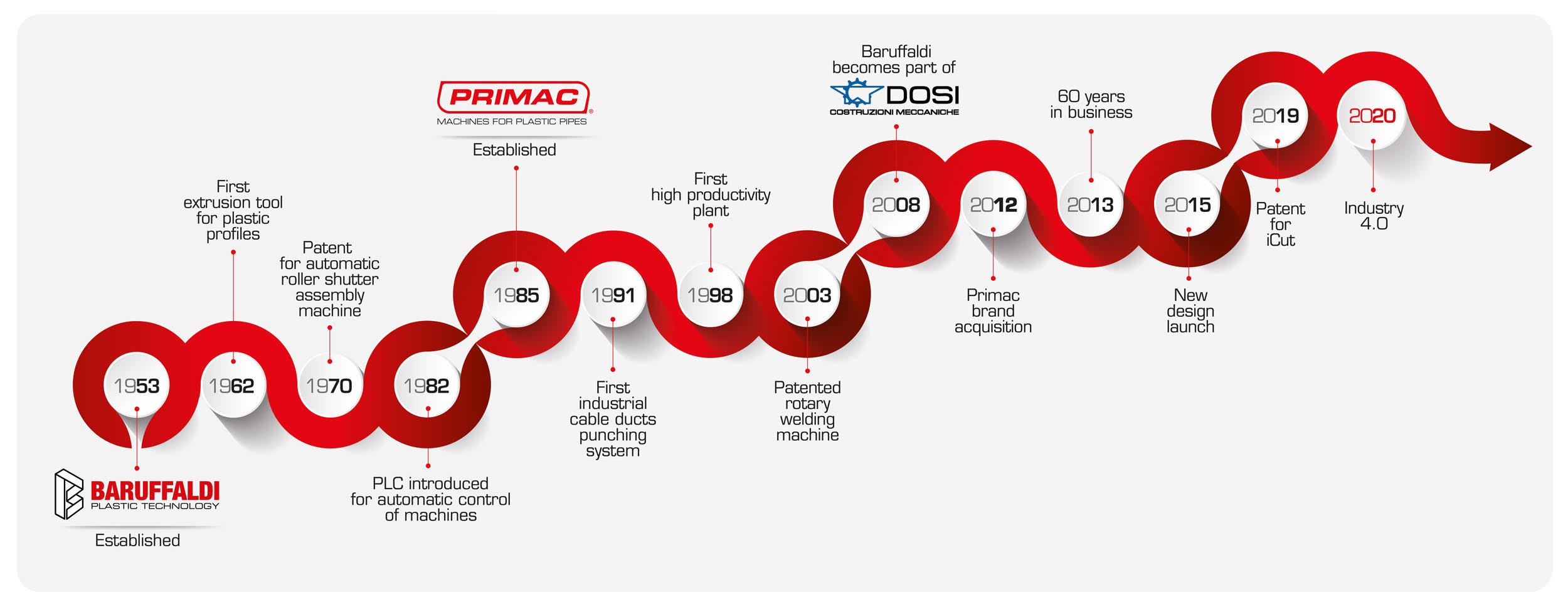

Baruffaldi is a company with a strong tradition, but, at the same time, dynamic, flexible and cutting-edge, to constantly meet the customized needs of its customers. Since it was established in 1953 Baruffaldi has created a solid reputation at an international level as a manufacturer of extrusion tools and extrusion lines, automatic in-line and off-line machines for plastic profiles, roller shutters, cable and installation ducts for the electrical industry as well as for special customized machines and turn-key projects. Together with the Primac brand, it also builds machines for processing smooth and corrugated pipes in PP, PE and PVC.

Together with the Primac brand, it also builds machines for processing smooth and corrugated pipes in PP, PE and PVC.

Baruffaldi – Primac are two brands that have one of the most complete range of downstream equipment machines in the world, both in the field of extruded plastic profiles and in that of pipes.

Baruffaldi-Primac are proud of their four areas of excellence:

In particular in the first two markets, the technological solutions are not only excellent, but Baruffaldi also holds the leadership.

Flexibility at the service of the customer, professionalism, earnestness, reliability, quality and Baruffaldi team’s constant commitment along with investments in technology, are the strengths that lead the company to challenge the market, growing to serve new segments and proposing itself as the ideal partner for developing or making final projects more productive.

Baruffaldi and Primac work in synergy with the activity of the Dosi Group, which owns them, covering the entire production process and thereby guaranteeing quality products and putting greater resources at the service of their customers.

In 2024 we opened an office in the USA to give immediate support to our american customers.

Baruffaldi serves manufacturers of PVC / PE / PP / PPR smooth and corrugated pipes, plastic profiles of the most varied sectors, such as roller shutters, doors and windows, cable trunkings and cable ducts, construction, automotive, furniture – design , electrical, electronic, health and bio-medical, lighting, ventilation-conditioning, etc. Baruffaldi commercial, technical and production staff offers the customer successful and high-profit solutions.

Sales, designers, mechanics and technicians work in synergy with customers and are aimed at the continued improvement of innovative, effective and competitive solutions, which are the key not only to our success but also that of the customers.

Baruffaldi takes care of its customers from the initial phase of feasibility study and customized design, during the construction, start-up and testing phase and in the next phase with an efficient assistance and spare parts service. Other services offered are reconditioning and storage of the facilities.

“Perfection is not attainable, but if we chase perfection we can catch excellence.“

Baruffaldi’s journey towards perfection travels along three main “highways”: attention to detail, both in the design phase and during the construction; the attainment of high performance levels that sets apart from the crowd and allows the company to offer customers high-productivity technology, that is rewarding over the years and, finally, the search for functional good looks because working in a more pleasant environment, as well as safer, is important, considering the time of our life that we spend at work.

Baruffaldi recipe for excellence stands on the craftsmanship because each solution is completely customized. Baruffaldi industrial products, fabricated with first class Italian and European materials, continue to transmit a sense of belonging to a system of values such as uniqueness, innovation and creativity which are applied in every step along the way in the production chain even though the reals is so specific and technical.

The design of Baruffaldi machines, compact and solid at the same time, brings out their ergonomics and ease of access to the work area. Because of the automatic plants modularity and the fact that most of them can be added to in the future or used in-line or offline, they grant end users the freedom to decide how to “do production” in proportion to their investment budget, available floor space and the market trends at that particular moment in time. The downstream equipment includes single or combo units, at various levels of complexity, which can be expanded according to need in order to give the greatest flexibility.

Baruffaldi customers know they can count on winning solutions, because while designing the technologies, the customer is always on focus. Potential customers should know, that when choosing Baruffaldi brand, they choose quality and a complete service, because they can completely entrust the company with everything for handling their turn-key project.